Title: A Study paper on Power Generation Methods – Conventional & Renewable

Author: Aniket Shirish Wadalkar, 3rd Year BTech, Electrical, Electronics and Power Department

College: Government Engineering College, Aurangabad

Abstract

‘Energy crisis’ is the word heard more than ‘Energy systems’ for last 20 years and we know why. There are some machines which would help to get rid of all this. One of them is ‘Symmetrical Motor or Alternator’ which not only differs in design, but also in efficiency and power dissipation from normal motor-generators. Since motors and alternators form basis of electrical engineering, Power generation using Symmetrical motor or alternator was an interesting and descriptive topic to learn. Its derivations, workings, construction might just help to challenge the crisis. Also, there‘re renewable options open to us as they always are; but severe shortages and wages of powers leads to find the newer ones from them. Power generation from salt water of the sea is of the techniques in that way as uses the simple chemical process of electrolysis; and along with power generation on a particular scale, it completes electroplating. But, being in an agricultural country India, finding a solution to irrigation and pumping system makes the justice. The power cuts and expenses of irrigation and pumping have worried the farmers and hence with them, the entire system; and solar pumps with certain specifications as explained join the crisis challenge So, by this attempt to elaborate some of the not well known power generation techniques, I hope their construction, working and importance are convinced.

Power generation by ‘Symmetrical Motor (or Alternator)’ –

‘A rotating machine which converts electrical energy into mechanical energy is called a motor; and which converts mechanical energy into electrical is called generator’. Those converted energies are used for power generation. Symmetrical motor is a motor similar to normal motor, but shape of football or sphere; not cylindrical like the former one. And, its slide slots are replaced by saw tooth slots.

Material required for various parts:

1) Yoke: Die cast iron, silicon steel (hot rolled).

2) Core and armature: sheets of Steel with Silicon (4 to 5%), IS 648-1970 Cast Iron (65%) with

Ferrous cobalt (35%)

3) Windings: Annealed high conductivity Copper, hard drawn Copper wire, super enamelled

Aluminium, Cadmium Copper and Beryllium copper 4) Shaft: Light weighed but mechanically strong Steel plate

5) Insulation: Mika, Fibrous Glass, Cotton fibre, Polyamide, epoxy thermosetting resin.

Working principle:

1) Faraday’s law: Emf induced in electrical circuit is directly proportional to rate of change of flux linkage.

2) Lenz’s law: Direction of induced EMF is such that it tries to oppose its own use of production. This emf produced is Motional emf.

3) Biot Savart’s law: force produced on account of interaction between a magnetic field & a current carrying conductor is, F=B*I*L*sinθ

Where: B→flux density,

I→current carried by the conductor,

L→length of conductor &

θ→angle between direction of current and direction of magnetic field.

Synchronous speed = 120*Frequency / No. of poles

EMF equation:

E: emf induced in rotor at slip‘s’,

Kc: coil span factor of stator winding,

Kd: distribution factor of stator winding,

Ø: flux per pole produced by stator MMF,

T: number of rotor winding turns in series per phase

Kw: winding factor.

E = 4.44 * kc * kd * sf * Ø * T (volts)

Kw = kc * kd

Design factors:

1) Electrostatic or Electromagnetic field.

2) In electromagnetic machine, value of flux density 1.6wb/metre square (max.) can be generated by

magnetic saturation, energy density in air gap about 1MJ/metre cube.

3) Mechanical Strength to be beard by body of machine.

4) Cost, durability & compliance with performance.

5) Ratio of air gap to pole pitch.

6) Shape of pole & type of winding on pole and armature.

7) Ventilation between holes in slots.

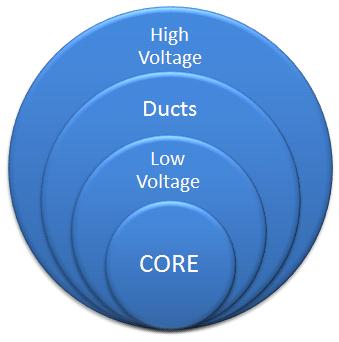

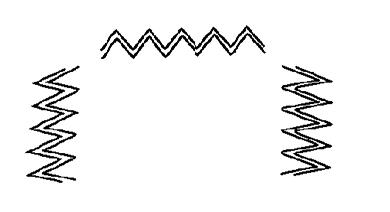

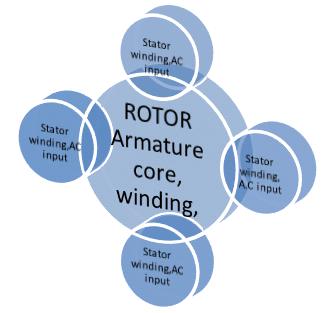

General schematic representation: Positions with respect to core

All windings:

Sectional or slice views:

1) Original machine with single winding –

3) Side view of rotor and stator:

Working: Its general working is totally similar to normal motors or generators.

Advantages for efficient power generation:

1) Air gap flux distribution factor is equal to

Area under flux distribution curve / (maximum ordinate*pole pitch)

and in case of horse shoe permanent magnet 3-shoe can be arranged in 3 different axes to give

symmetry. Hence power efficiency must increase.

2) There is no need of slot tooth; hence power generation is easy.

3) Skin effects are considerably reduced due to this type of construction.

4) The shorter length of shaft does not allow excessive, unbalanced magnetic pull during deflections.

5) Air gap and other mechanical parts, as a need of shape, are kept very small. This leads to power

factor improvement.

6) High power factor results in less current for same value of power. This causes very less heating

and saving of the conductor material during power generation.

Power generation by Sea-Water (Salt water; not tides)

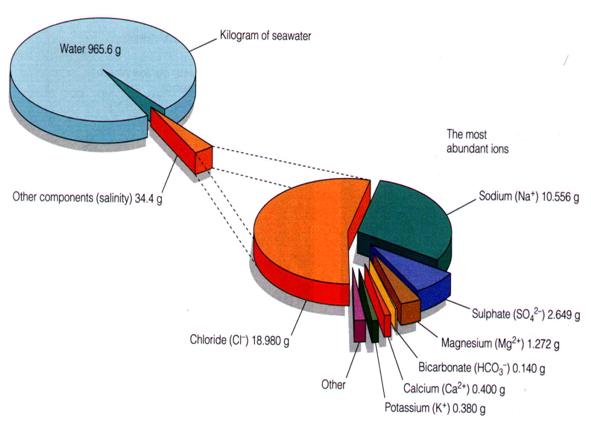

The 3rd most abundant thing to us after solar energy and gases is the sea-water (volume 1.37 billion km cubes). Not all, but a large part of it can be used for mechanical, electrical or some other power generation as per the experiment shown by Mr. Robert Gardener. Before going into that experiment, the overall composition of 1 kg sea water is as follows: :

Conductivity: The thermal conductivity of sea water at 25 °C is 0.6 W/mK, which increases with increase in temperature and decreases with increase in salinity.

Salinity: The sea water is not uniformly saline; this value is 3.1% to 3.8% or approximately 35 parts per thousand.

pH value: This value is also not constant; but ranges from 7.5 to 8.4.

Density: The density of surface seawater ranges from about 1,020 to 1,029 kg•m−3, depending on the temperature and salinity.

Marine organisms: Found in very large numbers, these creatures possess a large part of the sea water composition 0.7-2.2 million species (excluding the bacteria and viruses – they are almost too diverse to contemplate).

Small experiment for power generation by rotating turbines:

Equipments required:

1) Jar: To contain the sea (salt) water of capacity up to 20 liters.

2) Burner: To heat water up to 40°C to 50°C.

3) Zinc-coated nail.

4) 2 insulated wires with alligator clips on both ends.

5) Copper sheet as Cathode

6) Small motor (2Volts)

7) Rubber spacers and voltmeter

8) Small turbines: Made of any suitable material.

Working principle: The ‘Electrolysis’ principle which was used to light a lamp is used here, but not to light the lamp; to drive the motor to rotate the turbines.

Experimental arrangement:

Working:

1) If the Zinc coated nail is kept in the jar containing sea water, it will work as Anode.

2) Also, if Copper coated wire is placed into solution and taped to the other side of cup, it will work Cathode.

3) Separate the Anode and Cathode using rubber spacers.

4) Open the alligator clip on one wire by squeezing it, and attach it to the end of the zinc-coated wire sticking out of the solution.

5) Open the alligator clip on the other end of the wire, and attach it to the negative pole of the Voltmeter.

As the result of electrolysis, current starts flowing and due to this supply from the current,

motor starts running. This causes turbines to rotate which eventually generate power.

Advantages:

1) Along with power generations, electroplating can also be done.

2) Practically, no cost of fuel as in countries like India, there are large sources of sea water.

3) Very less chances of explosion during operation and transport as fuel is sea water.

4) After power generation, water can be used for other chemical processes.

5) There is no need of bridges for working.

6) Less labor work is required compared to other generating plants.

7) Grid free operation is possible.

Disadvantages:

1) Anodes and Cathodes should be replaced or repaired after regular time intervals.

2) Cost for metals used as anode and cathode may go high.

3) Output gradually decreases with time.

Mechanical Power generation for irrigation by Solar Pump:

Water irrigation is essential for agriculture. Most of the electricity bills gone beyond payable limits of the farmers are because of the excessive electricity required for the irrigation. It is therefore very important to choose another alternative for pumping.

A solar pump is a pump running on electricity generated by photovoltaic panels or the thermal energy available from collected sunlight. The operation of solar powered pumps is more economical mainly due to the lower operation and maintenance costs and has less environmental impact than pumps powered by an internal combustion engine. Solar pumps are useful where grid electricity is unavailable and alternative sources are not sufficient.

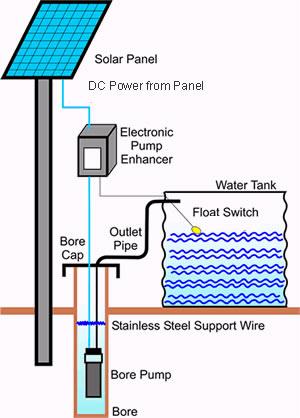

General schematic diagram for solar pump:

Construction and components:

1. The bore pump: As described, it operates on alternating or direct current supply for the voltage. Its functions for pumping water and its irrigation. It is mostly under the ground. .

2. Electronic pump enhancer with controller: This matches the output power that the pump receives with the input power available from the solar panels. Also, a controller usually provides a low voltage protection, whereby the system is switched off, if the voltage is too low or too high for the operating voltage range of the pump. This increases the lifetime of the pump thus reducing the need for maintenance.

Direct current motors are used for small to medium applications up to about 3 kW rating. Since DC systems tend to have overall higher efficiency levels than AC pumps of a similar size, the costs are reduced as smaller solar panels can be used.

3. Solar panels: The solar panels cost about 75% to 80% of total system. Conversion of solar energy into direct current electricity by photo voltaic cells is done there. The size of the Photo voltaic system is directly dependent on the size of the pump, the amount of water that is required (m³/d) and the solar irradiance available.

If an alternating current solar pump is used, an inverter is necessary that changes the direct current from the solar panels into alternating current for the pump.

4. Tank: If a new livestock tank is being built for the system, it is recommended to design it with a volume sufficient for three days worth of average demand. This is primarily to compensate for nights and cloudy days, especially when other power backup systems are not used. Make sure the internal velocities and pressures are appropriate for the pipe material and desired flow rates.

5. Mounting: A significant advantage of using a solar powered pumping system for livestock watering applications is it can be mobile. The PV array can be mounted on a trailer and set up on-site with the appropriate tilt for the panels. Due to how rough ranch roads tend to be, it is strongly recommended that the PV array be taken off of the rack and secured between layers of high-grade protective padding to keep them from being damaged during transit. If a quality solar-powered pump is purchased it can also be pulled from the old well and secured at the new location along with the PV array. A properly designed mobile system can provide a substantial cost savings when cattle are moved several times a year to areas in proximity of an accessible well and livestock tank.

6. Generator: If sufficient water storage is not available, some systems may need a backup generator to run the pump during low sunlight periods. If a generator is used with a DC pump, an inverter is usually required.

7. Solar Tracking System: This system follows the Sun along all of its axes. In some products the Sun is followed in X and Y directions. To increase the power yield, tracking systems are often sold by the manufacturers of Photo voltaic modules. Trackers assembled to the mounting bracket and can be controlled passively or electronically through part of the converted energy from the Photo Voltaic array. Passive trackers contain liquid (often Freon) that when heated from the sun moves from one cylinder to another causing the rack to tilt more into the sun. .Solar tracking systems improve the yield by maximum 40% at certain latitudes.

8. Sand Shroud: A sand shroud may be needed around the intake zone of the pump. Sand shrouds are recommended for use in wells that have high sediment loads or that were not properly installed. They are particularly recommended in open boreholes which are not screened through the saturated zone of the well. The pump manufacturer can usually provide a compatible sand shroud.

The flow rate of the solar pump can be estimated using following formula:

Flow rate per minute = Demand*Hours / (Peak sunlight hours * 60)

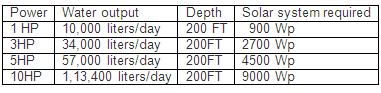

The solar pumps are available in wide ranges. Water at 500 feet (FT) below ground level can also be pumped, which can be operated up to 10 to 12 Horse Powers (HP). Following tabular description is for the depth of 200 FT below the ground level:

Hence, water output increases with decrease depth of water source.

Life:

1) Solar modules are warranted for about 25 years.

2) Water pump made of stainless steel will have life of at least 10 years.

3) Controller is also designed to have life of 10 to 13 years.

Advantages:

1) These pumps have ability to work on both solar energy and grid electricity.

2) Construction of these systems may be done in a complimentary way with solar generators or wind mill plants or both.

3) Can operate in cloudy weather; even at night.

4) Efficiency increases and maintenance and running cost decreases if brushless direct current motors are used.

Disadvantages:

1) Initial costs are high (in Lacs of rupees)

2) There are limitations regarding place, depth, latitude and location for construction.

References:

- Advantage Maharashtra Expo 2014

- Concise OED Alternative Energy. Accessed May 2, 2008.

- Power Generation Technologies, Paul Breeze

- Electricity Generation using Solar Thermal Technology, Wikipedia Book

- Power Generation Handbook : Selection, Applications, Operation, Maintenance,Philip Kiameh

- http://www.sciencedaily.com/releases/2012/03/120301143731.htm