Technical Paper Title: ENERGY STORAGE ULTRACAPACITORS

Authors: M.SPANDANA & A.JAGRUTHI, 2nd BTech, EEE

College: VASAVI COLLEGE OF ENGINEERING, IBRAHIMBAGH, HYDERABAD

ABSTRACT:

Almost everything we use requires a battery (computers, mobile cell phones, flashlights, hybrid electric cars, personal entertainment devices like Ipod, etc). As functionality increases in the digital age, so has our reliance on the traditional battery. The battery has not progressed far beyond the basic design developed by Alessandro Volta in the 19th century. Until just now. Recent work at MIT’s Laboratory for Electromagnetic and Electronic Systems (LEES) offers the most economically viable alternative to conventional batteries in more than 200 years. The Ultracapacitor is both a battery and a capacitor.

INTRODUCTION:

EVOLUTION OF ‘ULTRA’

The capacitor then evolved into an electrostatic capacitor where the electrodes were made up of foils and separated by paper that served as the dielectric. These capacitors are used in the electronic circuit boards of a number of consumer applications. Here the surface area of one electrode was increased by etching the electrode to roughen it, reducing the thickness of the dielectric and using a paste-like electrolyte to form the second electrode.

An ultra capacitor however has a significantly larger storage area.

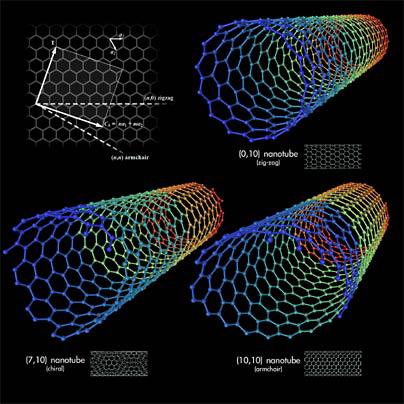

Ultracapacitors are made with highly porous carbon materials. These materials have the capability of increased surface areas ranging greater than 21,500 square feet per gram. The separation distance between the charged plates is reduced significantly to nanometers (10(-9) cm) in the ultracapacitors by using electrolytes to conduct the charged ions . Although they are compared to batteries from the application perspective, ultracapacitors are unique because there are no chemical reactions involved. They are considered efficient as they can quickly store and release electrical energy in the ‘physical’ form.

Ultracapacitors could allow laptops and cell phones to be charged in a minute. Unlike laptop batteries, which start to lose their ability to hold a charge after a year or two (several hundred charge/discharge cycles), ultracapacitors have hundreds of thousands of charge/discharge cycles and could still be going strong long after the device is obsolete. ‘Theoretically, there’s no process that would cause the [ultracapacitor] to need to be replaced.’

CHARECTERISTICS

The significant characteristics of ultracapacitors are:

• Low internal resistance in comparison with batteriesHigh power density due to high discharge currents

• Ability to operate at temperatures as low as -40°C

• Effective capacitance for specific pulse widths

• Low equivalent series resistance (ESR)

• Higher cycle life, making them suitable for automotive applications

HOW ULTRACAPACITOR WORKS???

Ultra capacitors & Super Capacitors store electricity by physically separating positive and negative charges— different from batteries which do so chemically. The charge they hold is like the static electricity that can build up on a balloon, but is much greater thanks to the extremely high surface area of their interior materials.

An advantage of the ultracapacitor is their super fast rate of charge and discharge… which is determined solely by their physical properties. A battery relies on a slower chemical reaction for energy.

A disadvantage of an ultracapacitor is that currently they store a smaller amount of energy than a battery does.

Ultracapacitors are very good at efficiently capturing electricity from regenerative braking, and can deliver power for acceleration just as quickly. With no moving parts, they also have a very long lifespan – 500,000 plus charge/recharge cycles. Ultracapacitors are currently used for wind energy, solar energy, and hydro energy storage.

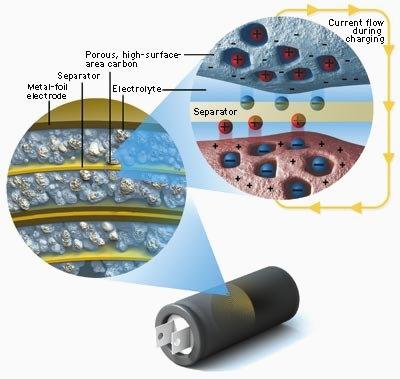

An ultra capacitor, also known as a double-layer capacitor, polarizes an electrolytic solution to store energy electro statically. Though it is an electrochemical device, no chemical reactions are involved in its energy storage mechanism. This mechanism is highly reversible, and allows the ultra capacitor to be charged and discharged hundreds of thousands of times. Once the ultra capacitor is charged and energy stored, a load (the electric vehicle’s motor) can use this energy. The amount of energy stored is very large compared to a standard capacitor because of the enormous surface area created by the porous carbon electrodes and the small charge separation created by the dielectric separator.

TECHNICAL DESCRIPTION

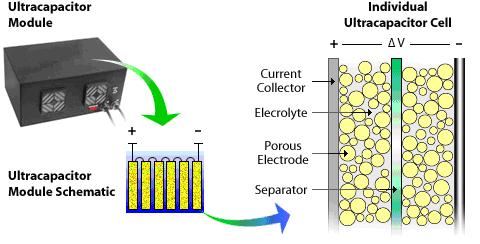

An ultracapacitor can be viewed as two non reactive porous plates, or collectors, suspended within an electrolyte, with a voltage potential applied across the collectors. In an individual ultra-capacitor cell, the applied potential on the positive electrode attracts the negative ions in the electrolyte, while the potential on the negative electrode attracts the positive ions. A dielectric separator between the two electrodes prevents the charge from moving between the two electrodes.

Electrical energy storage devices, such as capacitors, store electrical charge on an electrode. Other devices, such as electrochemical cells or batteries, utilize the electrode to create, by chemical reaction, an electrical charge at the electrodes. In both of these, the ability to store or create electrical charge is a function of the surface area of the electrode.

For example, in capacitors, greater electrode surface area increases the capacitance or energy storage capability of the device.

As a storage device, the ultracapacitor, relies on the microscopic charge separation at an electrochemical interface to store energy. Since the capacitance of these devices is proportional to the active electrode area, increasing the electrode surface area will increase the capacitance, hence increasing the amount of energy that can be stored. This achievement of high surface area utilizes materials such as activated carbon or sintered metal powders. However, in both situations, there is an intrinsic limit to the porosity of these materials, that is, there is an upper limit to the amount of surface area that can be attained simply by making smaller and smaller particles. An alternative method must be developed to increase the active electrode surface area without increasing the size of the device. A much more highly efficient electrode for electrical energy storage devices could be realized if the surface area could be significantly increased

: ENERGY STORAGE: Solar Energy – Wind Energy – Hydro Energy

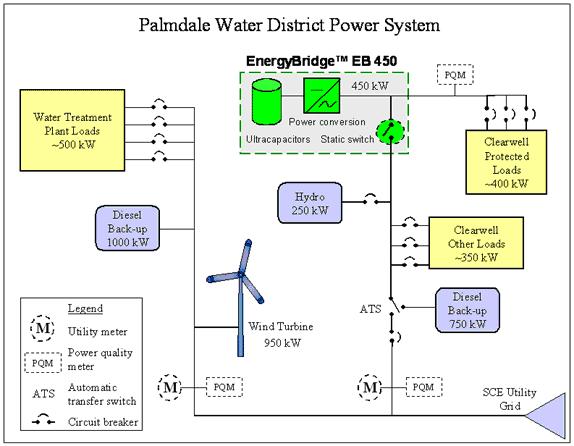

Using the ultra capacitor as an energy storage device has been making a lot of ground lately. Ultracapacitors have close to 100 percent efficiency and can be recycled up to 500,000 times. The introduction of standard battery-sized ultracapacitors is a move that has the potential to significantly improve market acceptance of ultracapacitors in a variety of applications and hybrid electric vehicles (HEVs).

Large back up power users such like manufacturers and utility providers have been reluctant to move from their traditional lead-acid batteries because they are unfamiliar with the new ultracapacitor technology. All of this in spite of of the significant advantages like greater reliability and efficiency. The tide is turning though… more and more companies are becoming aware.

It was recently noted by Miriam Nagel: “Environmental issues are now coming into play in the selection of advanced energy storage technologies.” “Environmentally friendly technologies such as flywheels and ultracapacitors – also called supercapacitors – may soon get a lot more consideration in the energy storage markets.”

One of the issues that has slowed the ultracapacitor market is the high cost of integrating them into new designs. It’s just now becoming known that ultracapacitors can now be produced at half the cost of its earlier earlier versions and the savings are likely to be passed on to original equipment manufacturers (OEM)

The diagram shows energy storage using an ultracapacitor

APPLICATIONS

In terms of applications, ultracapacitors serve three distinct areas.

Uninterruptible Power Supply (UPS) Systems

The first is for temporary backup power in electronic devices. Before the use of ultracapacitors for backup power was discovered, batteries were the only source of backup power for secondary, short-term emergency power particularly when the primary source of power is insufficient to sustain normal functions. However, ultracapacitors are being used as an alternative to batteries due to their large capacity (capacitance) and energy density. In UPS systems, ultracapacitors continue to charge from the primary power supply and provide a backup power source when the primary source fails. One of the main advantages of ultracapacitors is its ability to provide instantaneous supply without any delays that can impair mission-critical applications. Another application of ultracapcitors that is being considered is the short term bridge power applications for stationary UPS that are augmented with fuel cells. Ultracapacitors are best suited to provide start up as well as peak load buffering. Instead of additional battery storage, ultracapacitors serve as the ideal way to reduce the size of the system as well as the costs.

Typical examples of ultracapacitors are systems on the premises of critical-load utilities such as hospitals, banking centers, airport control towers, and cell phone towers. The critical time between a power outage and the onset of a generator is bridged effectively by ultracapacitors, which provides power in the order of milliseconds to a few seconds.

Transportation

The next largest market for ultracapacitors is in the transportation industry. They are widely known for their use in tandem with other energy sources particularly batteries. The primary source, however, is the engine while ultracapacitors serve as the secondary source. Here their main advantages lie in their ability to perform well in extremely low temperature up to -40°C along with their small size and lightweight design in comparison to batteries.

Consumer Electronics

Ultracapacitors find their widest use in the consumer electronics market where they serve as backup sources for memory, microcomputers, system boards and clocks. Another huge market for ultracapacitors is the mobile phone market where they are increasingly used to reduce the size and performance of mobile phones.

HYBRID ELECTRIC VEHICLES

Most every car manufacturer has announced plans for develop their own electric car using some sort of ultra-capacitor battery.

Perhaps the most promising near-term alternative to fuel cell driven vehicles is Hybrid Electric Vehicle (HEV or EV) technology. HEV technology combines the best characteristics of fuel-driven engines, electric motor drives, and energy storage components. It is designed with a combustion engine that functions as the primary power source, and an electric power storage system that functions as the secondary power source. The presence of the secondary power source allows designers to size the combustion engine for cruising power requirements.

• Hybrid Vehicles are good for the environment. They can reduce smog by 90 percent and they use far less gasoline than conventional cars.

• Hybrid Vehicles are economical. They can get up to 55 to 60 mpg in city driving, while a typical SUV might travel 15-20 miles per gallon, or use three times as much gas for the same distance!

• Hybrids are better than all-electric cars because hybrid car batteries recharge as you drive so there is no need to plug in. Also, most electric cars cannot go faster than 50-60 mph, while hybrids can.

ENERGY STORAGE ULTRACAPACITORS-THE SITRAS SES SYSTEM

The local transport authorities of several cities such as Cologne and Madrid are now using an innovative energy storage system that is also designed to recover braking energy. This system is called SITRASSES, and it was developed by the engineers of Siemens Transportation Systems. It allows system operators to achieve energy savings of up to thirty percent. SITRASSES also makes a decisive contribution to stabilizing the voltage

on the network, which enhances the reliability of mass transit systems by avoiding sudden power outages when several trains or trams draw power at the same instant and drag the voltage down. Another example that has shown similar benefits using Maxwell’s ultracapacitors is the MITRAC system from Bombardier Transportation.Underground trains that feed braking energy back into the electricity supply system first entered regular service around twenty years ago. When such a train brakes, its electric motor acts as a generator and feeds the regenerated energy back into the supply lines. However, this excess energy can only be used if there is an increased energy demand at the same time somewhere

else in the network, which can for instance arise from a train just starting off. However, this is relatively rare. Otherwise, only approximately sixty percent of the regenerated energy can be used in normal operation. The remainder is dissipated as heat in the braking resistors of the vehicles, without being put to good use. Around six years ago, the engineers at Siemens started thinking about an energy storage system that could absorb braking energy and release it later on to trains that are starting to move. Simulations and practical tests in various cities showed that using a suitable energy storage system operationally for around 22 hours per day could reduce the annual primary energy demand by as much as 500,000 kilowatt-hours. That corresponds to a reduction of CO2 emission of 300 tons.Besides batteries, flywheels and capacitors, the types of devices that could be used for energy storage include exotic solutions such as superconductive motors. However, such motors are presently still too expensive for practical use. First the engineers decided to use flywheel storage systems. However, after the first extended service tests, it was clear that they were not suitable for long-term use, due to their complex maintenance. Batteries are also less suitable due to their low peak power capacity, and their limited lifetime. The engineers, therefore, then concentrated on developing capacitor energystorage systems.

CHALLENGES

1. The foremost challenge is from traditional batteries such as the lead acid, lithium ion, nickel cadmium (NiCD), nickel metal hydride (NiMH) and others which existed in the market for more than hundred years

2. Equivalent Series Resistance values can be optimized only with efficient packaging of the ultracapacitor

3. Cost of raw materials are significantly high and plays an important role in the pricing of ultracapacitors

4. Adoption rates are only gradually increasing as end-users realize the benefits of ultracapacitors

CONCLUSIONS

Many of the above mentioned applications are still in the early commercialization stage and the only area seeing widespread use of ultracapacitors is the consumer market where ultracapacitors are used as passive electronic components. The introduction of higher voltage technologies is keenly awaited in the industry and their benefits are expected to be far reaching. However, research is gaining momentum and vendors the market is expected to see widespread adoption of ultracapacitors as an alternative to existing battery technology.

REFERENCES

1. Automotive Engineering International, global vehicles pgs 1416,Dec. 2002

2. See, US Fuel Cell Council at www.usfcc.com

3. K. Miyadera, “Development of ES 3 Small Sized LowFuel Consumption Vehicle,” Toyota Technical Review, Vol. 52, No. 1, Sept. 2002, pgs. 2227

4. P. Rodatz, O. Garcia, L. Guzzella, F. Buchi, G. Scherer, A. Wokaun, “Performance and Operational Characteristics of a Hybrid Vehicle Powered by Fuel Cells and SuperCapacitors,” SAE International publication 2003010418, SAE special publication SP1741, Fuel Cell Power for Transportation 2003.