Title: Utilization of Solid Waste in Civil Engineering Applications

Authors: Arjun & Gautam Kumar, Department of Civil Engineering

College: Sant Baba Bhag Singh Institute of Engineering & Technology, Jalandhar

ABSTRACT: Global warming is the major issues of this decay which deal with the future of next generation .Pollution play a main role especially solid waste i.e. 1. HDPE/PET; 2.MPPW ;3.FLY ASH; 4.Construction Steel Waste , Which is a matter of environmental concern, it produce very harmful EFFECTS & directly affect the humans, So we focus to solve these problems and used as a Reinforcing material in different civil engineering application.

Key words: GLOBAL WARMING,HDPE/PET, MPPW, FLY ASH, SUBGRADE

Introduction

Today everywhere there are problems by plastic materials, fly ash and other materials so we use this material as fiber in civil application according to there properties, The reinforced soil technique allows the most any kind of fill soil, however the use of granular material having good drainage capacity and high internal friction angle is suggested. Earth structure such as highways and airport pavements, embankment, landfills, foundation earth slopes and retaining walls are built with soil reinforcement for improved safety against sliding or bearing failure and to improve the settlement response. In the present investigation HDPE/PET & MPPW (MEDICAL PACKING PLASTIC WASTE STRIPS) are used as reinforcing material. These fiber strips have adequate tensile strength and retain the same strength for lon span of time and steel waste is also used in concrete as a steel aggregate.

1. HDPE/PET

CASE OF INVESTIGATION

Global warming is the major issue of this decay which deal with the future of next generation. Pollution play a main role specially solid waste i.e. Plastic waste is the major source of solid waste pollution. Every year more than 500 billion plastic bags are used which is a matter of environment concern, It produce very harmful chemicals & directly affect the humans, so we focus to solve the problem and use it as a reinforcing material. Innovative construction technologies involving partially/full replacement of natural resources with relevant solid waste in construction is a step in mitigating afore mentioned problem.Hence, in present investigation utilization of HDPE (High density polyethylene strips) and PET (polyethylenterefltalate) is tried as an alternative for reinforcement of soils. Usage of such plastic waste will surely reduce the problem of solid waste disposal. The main objective of present investigation is the effect of waste plastic strip in the form of discrete fibers are studied.

IT’S UTILIZATION

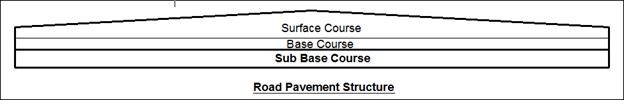

The fiber strips are mixed in the sub base course of road pavement, it increase the bearing capacity. which is show in fig.no.1

BENEFITS

- Use higher percentage of plastic waste

- Increase the strength and performance of the road pavement.

- Avoid disposal of plastic waste by incineration and land filling.

- Add value to plastic waste.

- Generate jobs for rag pickers.

2. FLY ASH

CASE OF INVESTIGATION

Fly ash, also known as flue ash is one of the residues generated in combustion, and comprises the fine particles that rise with the flue gases. Ash which does not rise is termed bottom ash. In an industrial context, fly ash usually refers to ash produced during combustion of coal. Coal ash is also danger for environment as well as human health. After study the property of fly ash we know that fly ash is an effective agent for chemical or mechanical stabilization of soils, Soil density, water content, plasticity and strength performance of soils. Typical applications include: soil stabilization, soil drying and control of shrink-swell.

IT’S UTILIZATION

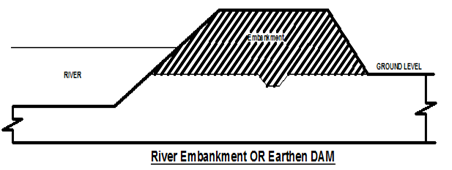

Fly ash properties are unusual among engineering materials. Unlike soils typically used for embankment construction, fly ash has a large uniformity coefficient and it consists of clay- sized particles. Engineering properties that affect the use of fly ash in embankments include grain size distribution, compaction characteristics, shear strength, compressibility, permeability and frost susceptibility. Nearly all the types of fly ash used in embankments are Class F.see as in fig.no.2 In other way to utilizing it is following:

• Fly ash in stabilized base course.

• Fly ash in structural fills.

• Fly ash in soil improvement.

• Fly ash in asphalt pavements

• Fly ash Portland cement concrete

Environmental Benefits

Fly ash utilized specially in concrete, has significant environmental benefits included. (1) Net reduction in energy use and greenhouse gases and other adverse air emissions when fly ash is used to replace or displace manufactured cement, (2) Reduce in amount of coal combustion products that must be disposed in landfills, (3) Conversation of other natural resources and materials, (4) Control air pollution.

Technical Benefits

- Eliminates need for expensive borrow materials

- By improving subgrade conditions, promotes cost saving through reduction in the required pavement thickness.

- Improved workability

- Increase resistance to sulfate attack

- Lowered costs

- Reduced shrinkages

3. WASTE STEEL

In civil construction steel is used in a major amount. Generally in civil construction we saw that the steel was wasted i.e. steel bars of different- different diameters and other steel sections or channels. The main causes of wastage are resulted from cutting, damages during storage and rusting also from a major part of wastage.

| Average material wastage among different types of projects |

| TYPE OF PROJECT Average Material Wastage |

| Public Housing 3.95 % |

| Private Housing 5.32 % |

| Private Commercial 3.94 % |

| Composite Building 5.07 % |

| Industrial 3.00 % |

| Monastery 4.37 % |

| School – % |

IT’S UTILIZATION

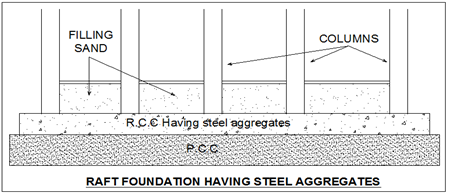

These wastage steel bars are chopped in small size as the course aggregate maximum size then it mixes into the concrete for various structure members like raft foundation.

Benefits

- Increase the compressive and tensile strength

- Reduce the volume of course aggregate

RESULTS

1.HDPE/PET

• Control solid waste pollution

• Increase the bearing capacity of soil

• Good properties of tensile strength

• Cheaper foundation.

o Grater resistance to weathering due to chemically inert PET and HDPE;

o Less stress on foundation due to lighter blocks;

o Variable strengths ( depend on size and nature of plastic aggregate);

o Better shock absorption

2. Fly ash

• Fly ash is a pozzolanic in nature and contains less than 20 % lime ( CaO). Possessing pozzolanic properties to embankments. And other civil construction

• Increase the bearing capacity of soil

• Good binding material

• Increase durability

3. Waste steel

• Increase tensile strength

• Good compressive stenth

• Concrete member had the quality to resistance the shear failure

CONCLUSIONS

1. Reduction in the amount of plastic waste present in the environment and a reduction in PET and HDPE waste entering landfill sites (anything that fills a landfill slower is a good thing)

2. Creation of jobs (collection of PET and HDPE materials).

3. Use this as reinforinsed flexible pavements

4. Eco-friendly and light weight construction

5. Fly ash concrete pavement will improve the resistance of the concrete to sulfate attack.

6. The concrete will be more resistant to road salts and freeze/thaw action as well as reduced alkali/silica reaction.

7. In many areas of the country, fly ash also can help keep the initial cost of concrete pavement competitive with asphalt pavements.

8. Steel waste retain the strength for long pan time

References:

1. Chelsea Centre for Recycling and Economic Development. (July 2002) Technical Report Plascrete: Lightweight, Portland cement Concrete Product

2. Waste Management: Solid, Liquid, Hazardous, Bio-medical and Electronic Waste PLAS-CRETE: Manufacture of Construction Blocks with shredded PET and HDPE Karen Alleyne, B.Sc. 3.. Ismail, Zainab Z., and Enas A. Al-Hashmi. “Use of waste plastic in concrete mixture as aggregate replacement.” Waste Management.

4. Al-Hadidy A.I., Yi-qiu Tan (2009), “Effect of polyethylene on life of flexible pavements”, Construction and Building Materials, Vol. 23.