Title: Biodiesel Production from Animal Fats and Mahua Oil and Its Effects on the Diesel Engine with Ethanol-Diesel Blends

Authors: D.S.Darunde, Asst. Professor, Mechanical Engineering, IBSS College of engineering, Amravati, SGBAU, Maharashtra

Ashish Dubey, Asst. Professor, Mechanical Engineering, S.B.Jain College of Engineering, Nagpur, RTMNU, Maharashtra

ABSTRACT

Biodiesel refers to a vegetable oil or animal fat-based diesel fuel consisting of long-chain alkyl (methyl or ethyl) esters. Biodiesel is typically made by chemically reacting lipids (e.g. vegetable oil, animal fat) with an alcohol producing fatty acid esters. Biodiesel is meant to be used in standard diesel engines and is thus distinct from the vegetable and waste oils used to fuel converted diesel engines. Biodiesel can be used alone, or blended with petrodiesel. Biodiesel can also be used as a low carbon alternative to heating oil. Biodiesel is produced by transesterifying the oil or fat with an alcohol (methanol/ethanol) under mild conditions in the presence of a base catalyst. The present paper discusses the production of biodiesels by animal fats & mahua oil as a fuel, the fuel properties, environmental effects including exhaust emissions and co-products. This paper also shows the use of glycerol which is the by product of transesterification process. The performance of the C.I. Engine using mixed biodiesels with methanol-diesel blends is also discussed.

Keywords: animal fats oil, blends, ethanol, mahua oil, transesterification

INTRODUCTION

Due to continuous usage, huge dependency & depletion in feedstock availability concerns and environmental problems the biodiesels attracts many researchers for the alternative source of energy. The biodiesels are produced by biological sources, among them lipid materials such as fats and oils have received increasing attention. Biodiesel, which is defined as the mono-alkyl esters of vegetable oils or animal fats, obtained by transesterifying oil or fat with an alcohol [1, 2]. The paper shows the production of biodiesels from Animal fat oil & Mahua oil, analysis of the various properties of biodiesels.

As the study [3] conducted, 20% biodiesel combusting internal diesel engines discharge polluted matters 20% less, carbon monoxide 12% less, fine dust 12% less, NOX 2% more, SOX 20% less, aromatic chemicals 13% less than those of diesel fuel. The reason for NOX incremental is that, again, more oxygen amount than diesel fuel. For biodiesel usage practice for agricultural tractor [4], more biodiesel fuel, about 30 to 40%, for tractor operation such as tilling and ploughing was needed than light oil. The biodiesel is produced by Mahua oil which is widely available in India and neighbouring countries. The mahua oil comes in the category of non edible vegetable oils [5], Mahua oil has an estimated annual production potential of 181 thousand tons in India [6]. Mahua trees are grown in drought prone areas and are abundant in several parts of India. Use of mahua oil methyl ester (MEMO) as the renewable substitute fuel for diesel will reduce the diesel consumption. The biodiesel is also produced by animal fats. In Korea, about 400 thousand tons of animal-fats are produced annually that can be transformed to biodiesel of 315 thousand kl. Cow fats and swine fats are the main resource for animal-fats biodiesel production. Animal-fats biodiesel yielding in USA is about 450 million litres in 2008 that was taking up 20% of total biodiesel production amount. Biodiesel can be an alternative fuel for heating fuel in the hot air heater for greenhouse heating.

PRODUCTION OF BIODIESEL

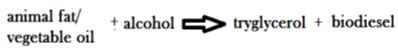

The production of biodiesel by transesterification process can be shown as:

ANIMAL FATS OIL PRODUCTION

Figure1: production of biodiesel figure2: separation of biodiesel and glycerol

Biodiesel is produced from the triacylglycerol-containing material by means of a transesterification reaction. In this process, alcohol (methanol/ethanol) and animal fats are mixed in the molar ratio of 6:1, heated at 60-650C for 1hr and the ambient pressure in the presence of catalyst such as NaOH/KOH. Before that, animal fat gets heated up to 105-1100C so that it will be converted into fat oil then in the separate flat bottom flask, alcohol and NaOH/KOH (2% of fat)are mixed exothermic reaction take place. This mixer is then added to heated fat and keep it at 60-650C for 1hr. After this, it is poured into a bottle so that biodiesel and glycerol get separated as shown [7].

MAHUA OIL

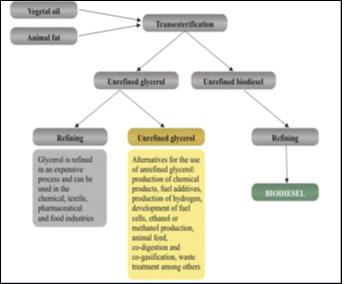

Mahua oil methyl ester (MOME) was prepared by using alkali catalyst as sodium methoxide by transesterification process. In the transesterification reaction excess of ethanol is used to cause fast reaction and high degree of conversion [8]. The transesterification requires an alkali catalyst such as NaOH, or KOH which are preferred due to their low cost and large availability. Although the ester is the major product, desired recovery of glycerol is important because of its industrial uses [8-9].

Figure3: The flow diagram of process of biodiesel product and uses of glycerol.

EXPERIMENTAL SET-UP

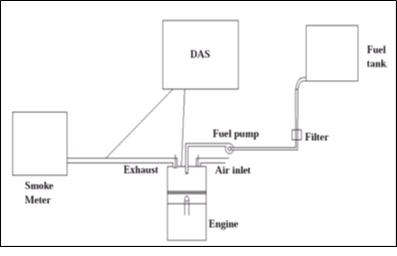

Experimental set-up for the use of biodiesel in diesel engine can be shown in the following figure:

As shown in the Fig. 2 experimental set-up, blended fuel is supplied to the engine through filter and fuel pump. Data acquisition system (DAS) is used to take readings of speed, inlet pressure, temperature, etc. and show output on the computer monitor. Smoke meter gives smoke reading per minute. Emissions such as NOx, CO, HC, and SO2 can be measured with the help of exhaust gas analyzer (not shown here).

In this experiment, the objective is the production of biodiesel from Animal fat oil & Mahua oil. After that mixing the two different biodiesels (i.e. from Animal fat & Mahua oil) in the ratio of 30% & 70% by volume, prepare its blends with methanol-diesel fuels, study their properties and to compare above blends with diesel (such B5E15D80, B10E15D75, B15E15D60, B5E20D75, B10E20D70 & pure diesel). Comparing considered performance parameter like brake specific fuel consumption (BSFC), brake thermal efficiency (BTE), Exhaust gas temperature (EGT) and smoke emission. Engine tests at constant engine speed 1500 rpm.

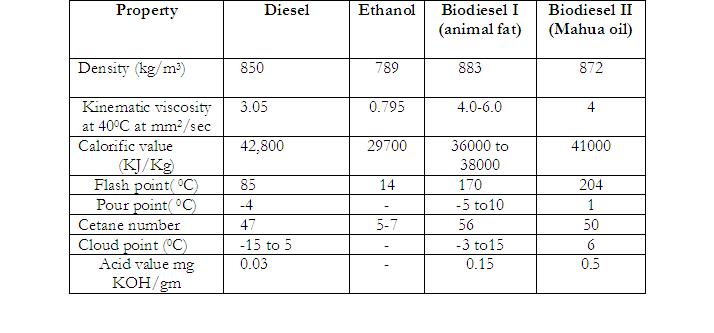

PROPERTIES OF DIESEL, ETHANOL AND BIODIESEL I (ANIMAL FAT OIL) AND BIODIESEL II (MAHUA OIL)

TABLE 1: PROPERTIES OF OILS USED

EXPERIMENTAL PROCEDURE

• ENGINE SELECTION

There is no difference of opinion that India is going to face a severe fuel crisis in future because fuel consumption has increased in all the vital sectors specially transportation, power and agricultural sector. As diesel engines plays an indispensable role in transportation and agriculture sector and as such diesel consumption will increase multifold in time to come. The diesel engine continues to dominate the agriculture sector in our country in comparison to spark ignition engine and have always been preferred widely because of power developed, specific fuel consumption and durability. A through description of combustion mechanism in diesel engine is beyond the scope of this study. However, it would be worthwhile to inform that the fuel is burnt in diesel engine by self-ignition at higher temperature and pressure conditions of the order of 600°C and 40 bar, respectively. Diesel as a fuel is injected into the combustion chamber at the end of compression stroke and after certain ignition delay; it burns to give the motive power. In India, almost all irrigation pump sets, tractors, mechanized farm machinery and heavy transportation vehicle are powered by direct injection diesel engines. Keeping the specific features of diesel engine in mind, a typical engine system, which is actually used widely in the Indian agricultural sector, has been selected for the present experimental investigations.

A single cylinder, four strokes, direct injection, naturally aspirated, air cooled computerized Diesel engine test ring is employed for the present work.

• ENGINE SPECIFICATION

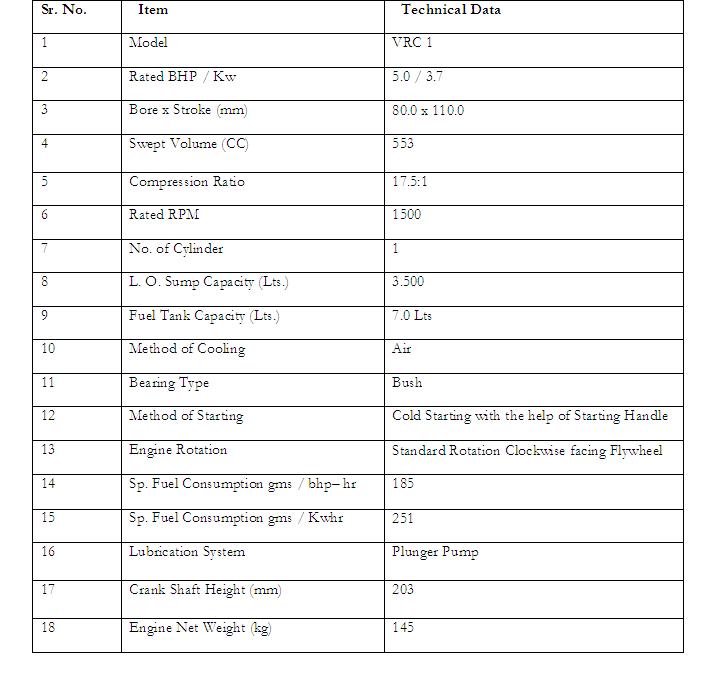

The specifications of the engine test rig used for present work are shown in table 2:

TABLE2: ENGINE SPECIFICATION

COMPARISON OF PERFORMANCE CHARACTERISTICS

For the comparison of performance characteristics, J. B. Heywood, a book on IC engine is used including some other research papers are used as described below:

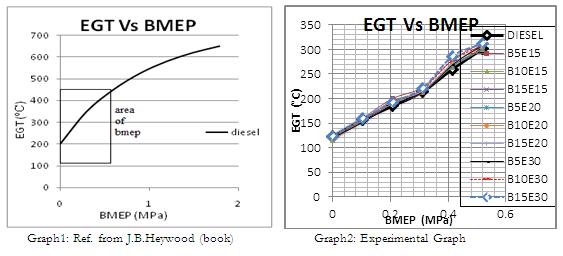

• COMPARISON OF EXHAUST GAS TEMPERATURE

As shown above, the graph of EGT Vs BMEP shows that exhaust gas temperature increases with increase in BMEP or LOAD. From Haywood, for diesel fuel this trend is validated. The experimental result (graph) shows that blends have higher EGT as compared to diesel fuel. A blend B15E30 shows highest EGT at the higher BMEP.

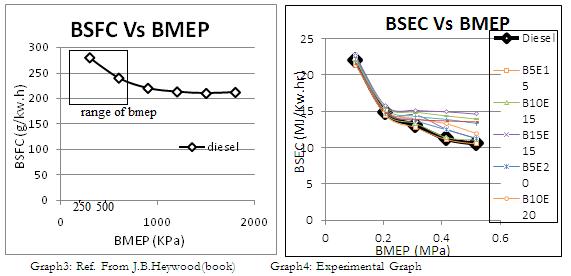

• COMPARISON OF BRAKE SPECIFIC ENERGY CONSUMPTION

Figure, shows the variation of BSEC with BMEP for different fuel blends. The comparisons of effect of BMEP on brake specific energy consumption between diesel and for different blends have studied. It is seen that brake specific energy consumption decreases when the BMEP is increased for all operations of biodiesel, ethanol, diesel and their blends (BED). It can be observed that brake specific energy consumption increases as compared to petro-diesel when blend is used for any given load or BMEP.

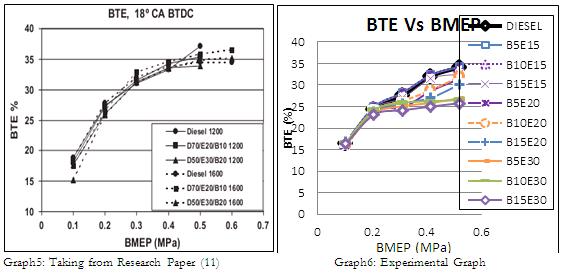

• COMPARISON OF BRAKE THERMAL EFFICIENCY

Generally, BTE of diesel is higher than that of all other fuels due to its higher calorific value. All the blends shows comparable trend of BTE with diesel fuel. This may caused by the available oxygen content in the blend which improves the combustion process despite the fact that oxygenated fuel has lower heating value. But the addition of ethanol reduces the viscosity which in turn increases the atomization. This leads to the enhancement of combustion. The blend B15E30 shows lower BTE than other fuel blends. A blend “B5E15”shows more BTE as compared to the diesel fuel. It’s because of more oxygenation of the combustion process and complete combustion as compared to other blends.

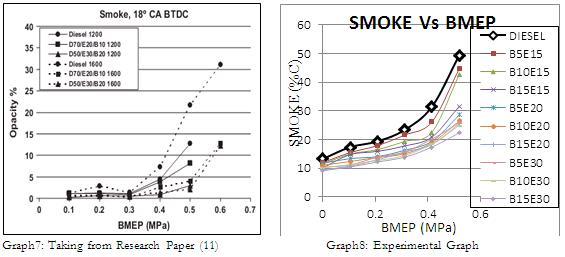

• COMPARISON OF SMOKE DENSITY

The smoke opacity increased with the load for diesel fuel, biodiesel, diesel-biodiesel-ethanol blends. The smoke is formed due to incomplete combustion. It is obvious that the smoke emissions are reduced with BDE. The smokes Opacity reduced with increase of ethanol percentage in diesel-biodiesel-ethanol blends with diesel. This has been showed by previous study. This may be assisted by the presence of the fuel-bound oxygen of the ethanol. More oxygen in fuel blends will give more CO2 emission as a result of good combustion.

CONCLUSION

The experimental study of the addition of biodiesels in ethanol-diesel blended fuel engine gave better engine performance and emissions characteristics. Diesel-biodiesel–ethanol blends (BDE) show better stability and can be used in diesel engine without major modification.

From all the result and discussion main conclusion came arise is that BDE in blend form is better to use in diesel engines. It shows performance closer to that of diesel on the expense of cost little higher. So these fuel blends proved as sustainable, suitable, prominent alternative fuel for all types of diesel engines.

FUTURE SCOPE

• There is need to further study for checking emission like NOx, CO2, CO, HC. From this study, we can compare more parameter.

• For an IC engine, fuel injection timing is a major parameter that affects the combustion phenomenon and exhaust emissions. The present study was carried on a diesel engine in which injection angle was kept constant. Injection timing variation has a strong effect on the exhaust emissions, especially on the NOx emissions, because of variation of temperature in the engine cylinder. Therefore, there is an urgent need to study effect of variable injection angle and injection pressure in conjunction with engine performance and emission characteristics.

• Also, it is strongly recommended that long term endurance test of these blends fuel powered IC engine may also be taken by future researchers.

• Turbocharging may be the good option for further research in this field to minimize the NOx emission.

REFERENCES

• Avinash Kumar Agarwal, “Biofuels (alcohols and biodiesel) applications as fuels for internal combustion engines”. Progress in Energy and Combustion Science 33, 2007, p. 233–271.

• Praveen R. Muniyappa, Scott C. Brammer, Hossein Noureddini, “Improved conversion of plant oils and animal fats into biodiesel and co-product”, Chemical and Biomolecular Engineering Research and Publications, 4-1-1996.

• Lee, J.S., “Commercialization status and prospects of biodiesel”. Journal of Structure,33, p. 45-49.

• Kim, Y.J., Kang, Y.K., Kang, K. C., Ryou, Y.S., “Fuel qualities of different biodiesels in the gun type burner”. Journal of Biosystems Engineering, 2008, 33, p. 124-129.

• Raheman H, Ghade SV (2007), “Performance of compression ignition engine with Mahua (Madhuca indica) biodiesel”. Fuel, p. 2568–73.

• Nadar K. N, Rana Pratap Reddy R. P, Anjuri E. R (2008), “Comparison of performance of biodiesels of mahua oil and gingili oil in dual fuel engine”. Thermal Science, p. 151-156.

• Darunde D. S., “Biodiesel production from animal fats and its impact on the diesel engine with ethanol-diesel blends: a review”. Volume 2, Issue 10, October 2012, p. 2250-2459.

• Padhi S.K.,Singh R.K., “Optimization of esterification and transesterification of Mahua (Madhuca Indica) oil for production of biodiesel”. Journal of Chemical and Pharmaceutical Research, Volume 2, Issue 5, 2010, p. 599-608.

• Montgomery R. “Development of biobased products”. Bioresource Technology, Volume 91, Issue 1, January 2004, p. 1-29.

• A book on Internal Combustion Engines by J. B. Heywood.

• Dattatray Bapu Hulwan, Satishchandra V. Joshi, “Performance, emissions and combustion characteristics of a multicylinder DI diesel engine running on diesel-ethanol-biodiesel blends of high ethanol content”, Applid Energy 88, 2011, p. 5042-5055.