Title: EXPERIMENTAL INVESTIGATIONS ON SOME GRADES OF AUSTENITIC STAINLESS STEEL

Author: Shubham Avinash Jadhav, IInd Year, Department of Mechanical Engineering,

College: Sinhgad College of Engineering, Vadgaon, Pune

ABSTRACT:-

The steel containing high content of both chromium and nickel are called as Austenitic stainless steel. There are many variation in chemical composition of these steels, but the most widely used steel contain 18 % of chromium and 8 % nickel with carbon content as low as possible. They are non-magnetic and possess greater resistance to corrosion and mechanical properties at elevated temperature.

There are some disadvantages of austenitic stainless steels (ASS). They have relatively low yield strength and hardness. The yield strength is very low proportion of tensile strength, typically only 40 to 45%. The comparable figure for mild steel is about 60 to 70%. Also the cost of the austenitic stainless steels increases due to use of expensive alloying elements especially Nickel.

Nitrogen alloying is nowadays preferred for improving the mechanical properties and special properties like resistance to erosion, corrosion, fatigue and creep of austenitic stainless steels.

In Experimental Investigations on some grades of austenitic stainless steel includes systematic study of nitrogen alloyed austenitic stainless steel .Comparison of ASS-316 and 21-4-N steel on the basis of microstructural and mechanical properties, has been undertaken for the present study.

KEYWORDS:- ASS-Austenitic Stainless Steel, Nitrogen alloying, Nitronic steel

1. INTRODUCTION:-

Steel is an alloy made by combining iron and other elements, the most common of these being carbon. When carbon is used, its content in the steel is between 0.2% and 2.1% by weight, depending on the grade. Other alloying elements sometimes used are manganese, chromium, vanadium and tungsten.

Varying the amount of alloying elements and the form of their presence in the steel (solute elements, precipitated phase) controls qualities such as the hardness, ductility, and tensile strength of the resulting steel. Steel with increased carbon content can be made harder and stronger than iron, but such steel is also less ductile than iron. Though steel had been produced by various inefficient methods long before the Renaissance, its use became more common after more efficient production methods were devised in the 17th century. With the invention of the Bessemer process in the mid-19th century, steel became an inexpensive mass-produced material. Today, steel is one of the most common materials in the world, with more than 1.3 billion tons produced annually. It is a major component in buildings, infrastructure, tools, ships, automobiles, machines, space craft, aircraft, nuclear power plants, appliances, and weapons, construction of roads, railways, other infrastructure. Most large modern structures, such as stadiums and skyscrapers, bridges, and airports, are supported by a steel skeleton. Nitrogen alloying is now a days preferred for improving the mechanical properties and special properties like resistance to erosion, corrosion, fatigue and creep of austenitic stainless steels[4,5].

1.1 STAINLESS STEEL:-

Nickel and manganese in steel add to its tensile strength and make austenite form of the iron-carbon solution more chemically stable, chromium increases hardness and melting temperature, and vanadium also increases hardness while reducing the effects of metal fatigue. In metallurgy, stainless steel, also known as inox steel or inox from French “inoxydable”, and is defined as a steel alloy with a minimum of 10.5% to 11% chromium content by mass. Stainless steel does not corrode, rust or stain with water as ordinary steel does, but despite the name it is not fully stain-proof, most notably under low oxygen, high salinity, or poor circulation environments. It is also called corrosion-resistant steel when the alloy type and grade are not detailed, particularly in the aviation industry. There are different grades and surface finishes of stainless steel to suit the environment the alloy must endure. Stainless steel is used where both the properties of steel and resistance to corrosion are required [1].

There are 150 grades of stainless steel of which 15 are widely used. According to chemical properties stainless steel divided in to 5 major types such as Austenitic, Martensitic, Ferritic, Duplex, and Precipitation Hardening.

The three basic types of stainless steel based on the type of major phases are:-

a) Austenitic

b) Ferritic

c) Martensitic

I. MARTENSITIC STAINLESS STEEL:-

Martensitic stainless steels make up the cutlery grades. They have the least amount of chromium, offer high hardenability, and require both pre- and post-heating when welding to prevent cracking in the heat-affected zone (HAZ).

II. FERRITIC STAINLESS STEEL:-

Ferritic stainless steels have 12 to 27 percent chromium with small amounts of austenite-forming alloys.

III. AUSTENITIC STAINLESS STEEL:-

Austenitic stainless steels offer excellent weldability, but austenite isn’t stable at room temperature. Consequently, specific alloys must be added to stabilize austenite. The most important austenite stabilizer is nickel, and others include carbon, manganese, and nitrogen.

Special properties, including corrosion resistance, oxidation resistance, and strength at high temperatures, can be incorporated into austenitic stainless steels by adding certain alloys like chromium, nickel, molybdenum, nitrogen, titanium, and columbium. And while carbon can add strength at high temperatures, it can also reduce corrosion resistance by forming a compound with chromium. It’s important to note that austenitic alloys can’t be hardened by heat treatment [2].

In order to check the suitability of material for various applications, in depth knowledge of the properties of material, effect of alloying element and effect of heat treatment and mechanical processing on its properties is necessary. To serve this purpose characterization study of material is generally carried out which includes systematic study of microstructural properties, mechanical properties and special properties like resistance to corrosion, erosion, wear, creep, fracture etc. in different conditions of the material like as received, heat treated, surface coated, mechanically processed etc.

2. SIGNIFICANCE OF PRESENT STUDY:-

There are some problems associated with ASS as listed below:-

• Low yield strength and hardness

• Formation of undesirable phases

• Cost of the austenitic stainless steels due to use of expensive alloying elements especially Nickel.

• Allergic reactions caused by Nickel

Considering these problems, the further research work has focused on following points:-

• Reducing Ni content

• Increasing Mo and N content

The requirement of high strength ductility and corrosion resistance leads to development of N-alloyed steel. Dissolved nitrogen distinctly improves strengthening as well as corrosion resistance of austenitic stainless steels. Hence austenitic stainless steels with reduced C and Ni contents and enhanced amounts of Mo and N in particulars were developed.

3. AIM OF PRESENT STUDY:-

The overall objective of the present research work can be prescribed as follows:-

• Study the composition of ASS-316 and 21-4-N steel

• Evaluate the mechanical properties of as received ASS-316 and 21-4-N steel.

• Study the correlation of metallurgical aspects and mechanical properties of proposed steels.

4. DESIGN OF EXPERIMENTS:-

The present research work aims at comparative study and as received grades of austenitic i.e. ASS-316 and 21-4-N steel.

Considering the objectives of the present investigation, the research work is subcategorized into the following heads:-

A. Study of chemical analysis of ASS-316 and 21-4-N steel.

B. Study of mechanical properties such as tensile test, impact test, hardness test between two proposed steels.

C. Study of effect of composition of ASS-316 and 21-4-N steel on their properties.

5. EXPERIMENTAL PROCEDURE AND TECHNIQUES:-

The methodology adopted for the systematic study of the proposed steels i.e. ASS-316 and 21-4-N steel. Optical metallography techniques were employed for studying the microstructural features of the steels in as received ASS-316 and 21-4-N steel. The mechanical properties were determined with the help of conventional techniques like tensile testing, Izod Impact testing and Vickers hardness testing. The advanced non-conventional techniques like wire cut EDM, CNC vertical milling machine, computerized UTM are also used.

5.1 MATERIAL SELECTION

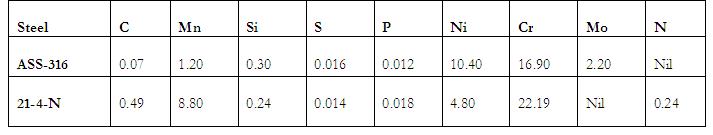

The ASS-316 and 21-4-N steel are selected for the present investigations. The chemical composition of both the steel is given in Table 1. Chemical Analysis: Test Method IS-228-1997.The ASS-316 was received from PRANAV ENGINEERING (W-206, M.I.D.C. Area, Ambad, Nashik-422 010) in the form of circular bar of dia. 12 mm. and also the rectangular bar of 10 x 10 mm cross-section. Also 21-4-N steel was received in the form of rectangular plate of 100 x 100 mm c/s. The specimens for various tests like metallographic examination, tensile test, impact test, hardness test, chemical analysis were machined from these raw materials with the help of EDM wire cut technique.

Table 1- Composition of ASS-316 and 21-4-N Steels

5.2 DETERMINATION OF MECHANICAL PROPERTIES:-

5.2.1 TENSILE TESTING:-

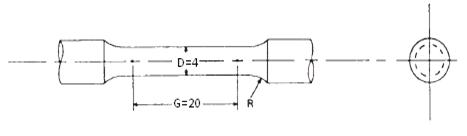

Standard cylindrical tensile specimens were prepared with a gauge length of 20.0 ± 0.1 mm and gauge diameter of 4.0 ± 0.1 mm, radius of fillet of min 4[0.156], length of reduced section of min 24[1.0] as per ASME E8/E8M-08 specifications as shown in Fig. 1. The tensile test was carried out at room temperature on as received samples of ASS-316 and 21-4-N steel utilizing SFA/TKG 25 KN (SR. NO. 99/03/TT-1) testing machine.

5.2.2 IZOD V-NOTCH IMPACT TESTING:-

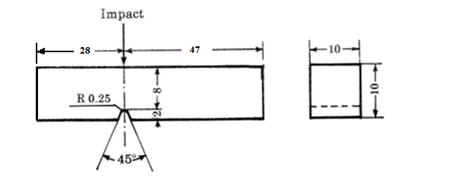

Standard Izod V-notch impact specimens of dimensions 10 x 10 x 75 mm were prepared as per ASTM E23-07 specifications as shown in Fig 2. and test was performed at room temperature utilizing make fine testing machine SFIT 300 ASTMT. Each value of impact strength is the mean of test values of 3 impact specimens.

5.2.3 HARDNESS TEST:-

Hardness measurement was carried out on the Vickers hardness testing machine using 10 kg load. Hardness test were carried out on machine VEB Werkstoffprufmaschinen 308/9012 made GDR.

Fig. 1-Dimensions of tensile specimen (all dimensions in mm) [6]

Fig.2-Izod test standard specimen (all dimensions in mm) [7]

5.3 METALLOGRAPHIC STUDY:-

Conventional polishing techniques were applied for preparing the samples of ASS-316 and 21-4-N steel in as received conditions for microstructural examinations. The polished specimens were etched with Villella’s Reagent/ Picric Acid (1 gm picric acid, 5 ml HCL, and 100 ml distilled water) and observed under the microscope melve varson INBT-2 for recording microstructures. For metallographic test, test method IS-77739 PART 5-2000 is used.

6. RESULTS AND ANALYSIS:-

Two grades of austenitic stainless steel i.e. ASS-316 and 21-4-N steel were tested for determination of various properties. The results of these tests and experiments are presented here.

6.1 COMPARATIVE STUDY OF ASS- 316 AND 21-4-N:-

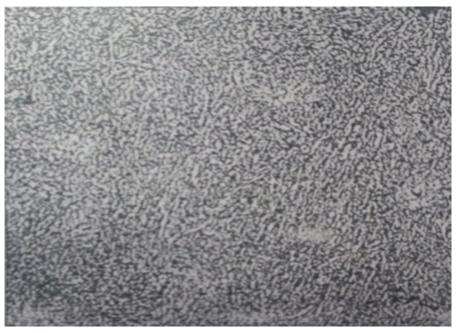

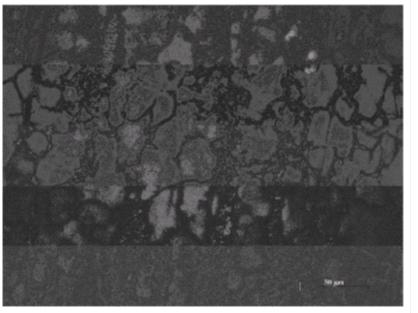

The microstructure of ASS-316 and 21-4-N steel are shown in Fig.3 and 4. Both the steel contains carbides (dark phase) in the matrix of austenitic (light phase). The schaffler diagram is generally referred to predict the resulting microstructure of stainless steel.

Fig.3- Microstructure of as received ASS-316 at 450x

(A)

(B)

Fig.4-Microstructure of as received 21-4-N steel at (A) 100x and (B) 450x

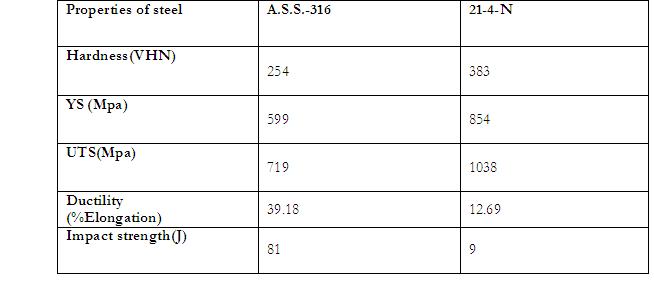

6.2 MECHANICAL PROPERTIES OF AS RECEIVED A.S.S.-316 AND 21-4-N STEELS:-

As per the standard practice described earlier, the important mechanical properties like hardness, yield and tensile strength and Izod V-notch impact strength of as received samples of ASS-316 and 21-4-N steels were determined. The mechanical properties of both the as received steels are listed in Table 2.

Table 2-Mechanical Properties of As Received ASS-316 and 21-4-N steels

7. CONCLUSION:-

Experimental investigation on ASS-316 and 21-4-N steels in as received conditions has been conducted. The important conclusions drawn from the present investigation are given below:-

1) Austenitic stainless steel is a widely used material in various applications. However there are some limitations of conventional ASS related to strength and hardness.

2) Alloy designing helps to acquire required properties of material by suitably controlling the composition of the alloy.

3) N-alloyed steels have been developed as the new Engineering material.

4) Microstructure plays an important role in deciding the end properties of the material. In ASS, Austenitic matrix provides the ductility and toughness but presence of carbides affects ductility and toughness. The ductility and toughness of 21-4-N steel is inferior to that of ASS-316 due to presence of carbides.

5) 21-4-N steel is harder and stronger than ASS-316. This is attributed to increase content of Cr, N and C (in the form of carbides)

6) The new grade i.e. 21-4-N steel is very well suitable for applications demanding high strength and hardness. These properties further improved by suitable heat treatment.

7) Nitrogen is freely available in nature. Also N-alloying techniques have been very well developed. Therefore, 21-4-N steel can be a promising and cost affective material for variety of applications.

8. SUGGESTION FOR FUTURE STUDY:-

1) The special properties of 21-4-N steel e.g. resistance to corrosion, erosion, heat etc. needs to be checked.

2) The properties of 21-4-N steel can be further enhanced by applying suitable heat treatment. This needs to be studied.

3) New grades of N alloyed steels can be studied for characterization by changing the composition.

REFERENCES:-

1. ^ “The Stainless Steel Family”. Retrieved 2009-11-12.

2. ^ a b “A non-rusting steel”. New York Times. 31 January 1915.

3. Aniruddha A. Gadhikar , Ashok Sharma , D.B. Goel, C.P. Sharma , S. K. Goel, Melting practice of Nitrogen Bearing Austenitic Stainless Steels , Proceedings of International conference , 59th Indian Foundry Congress, 11-13 February 2011, Chandigarh, 157-166

4. Aniruddha A. Gadhikar, C. P. Sharma, D. B. Goel, Ashok Sharma and S. K. Goel, Physical metallurgy and melting practice of nitrogen-bearing austenitic stainless steels, Indian Foundry Journal, Vol 56, No. 3, March 2010, 23-31

5. Aniruddha A. Gadhikar, C. P. Sharma, D. B. Goel, Ashok Sharma and S. K. Goel, Study of Carbides in Austenitic Stainless Steel, Indian Foundry Journal, Vol 56, No. 10, October 2010, 23-28

6. ASTM E 23-07a, Standard test method for notched bar impact tension testing of metallic materials, West Conshohocken, PA (July 2007) 1-26

7. ASTM E8M-08, Standard test method for tension testing of metallic materials, West Conshohocken, PA (March 2008) 1-8

8. C. P. Sharma, Engineering Materials- Properties and application of Metals and Alloys, PHP Publications, First Edition, August 2007.

9. Handbook of Comparative World Steel Standards.

10. R.M.Meenakshi Sundaram & Navaneetha Krishnan, Effect of N in austenitic stainless steel-an overview, Transactions of 57th IFC 2009, pp.189-196

11. V. G. Gavriljuk, Nitrogen in lron and Steel, ISIJ International, 36 (1996) 738-745