Title: Investigation on domestic solar cabinet dryer assisted with reflectors

Authors: Shrenik G. Yelttiwar, 4th Year B.Tech, Agricultural Engineering

Pooja N.Wajire, 4th Year B.Tech, Agricultural Engineering

Dr. S. R. Kalbande, Research Engineer

College: College of Agricultural Engineering and Technology, Dr.Panjabrao Deshmukh Agricultural University, Akola

ABSTRACT The project entitled “investigation on domestic solar cabinet dryer assisted reflectors” was undertaken with the objectives, to develop and fabricate cabinet solar dryer integrated with stainless steel reflectors system and evaluate its performance for drying of green chilli. The holding capacity of the dryer was 5 kg in a batch. Temperature in drying chamber, solar intensity, ambient temperature, relative humidity and air flow at outlet of the drying chamber were recorded.At no load test, the temperature in the solar dryer was found in the range of 32-60°C during day time in the month of winter( December 2013) at corresponding ambient temperature and solar intensity of 15-310C and 477.92 W/m2 (34.8–752.2 W/m2,respectively. Temperature in the dryer chamber was increased with attachment of stainless steel reflectors. The temperature in the drying chamber was found sufficient for drying in the winter season. Drying time for 5 kg green chilli for reducing moisture content of 83.93% to 3.21% (wb) was found to be 36 h in the solar dryer equipped with reflectors heating system, where as it took 104 h in the open sun drying.Thermal efficiency of the solar dryer with reflector system was found to be 36%. The dryer was found suitable for domestic use and drying of agricultural produce.

1.0 INTRODUCTION Chilli is a commercial crop in India. Tamil Nadu, Andhra Pradesh, Maharashtra and Karnataka are the major chilli producing states in India. In tropical countries, the uses of solar energy technologies have large scope compared to other countries. The introduction of solar drying system seems to be most promising alternative in reducing post-harvest losses (Esper et al., 1993). Open sun drying is the most commonly used method for drying of chillies in most of the developing countries. Drying under hostile climate conditions usually leads to severe losses in the quantity and quality of the product. On the other hand, mechanical drying is an energy consuming operation. Solar dryers are now being increasingly used since they are a better and more energy efficient option. Sun shines in India over an average 3000- 3200 h/yr delivering about 2000 kWh/m 2-yr of solar radiation on horizontal surface (Mani, 1980). This abundantly available solar energy can be used for drying of chillies. Mainly chillies contain moisture content in the range of 75 to 80 per cent at the time of harvesting. Reduction of moisture content to the desired level is the essential function of solar drying operation. The moisture removal involves two operations like low temperature heating and exhaust of moist hot air. Both the operations could be easily carried out by cabinet type solar dryer. Solar dryer has ample potential for drying products which required hot air less than 60oC. To develop domestic cabinet type solar dryer integrated with stainless steel reflectors. The use of solar dryer can results in the value addition of their produce. Multi-rack farm solar dryer using natural convection is developed for drying agricultural products. This farm dryer is efficient and no electric power is required while in use. It does not require any attention once the product is loaded. Keeping in view its relative merits such as less time to dry the product without the effect of dust, insect etc over the conventional drying system a study on solar energy application for drying candy was undertaken for energy conservation.

2.0 Material and methods: The materials used for the construction of the dryer are selected which could be easily maintained and repaired, and can be obtained locally at cheaper costs. The physical and chemical properties of the materials are strong enough to withstand heat, vibration, humid air, fatigue and stress without failure during operation.

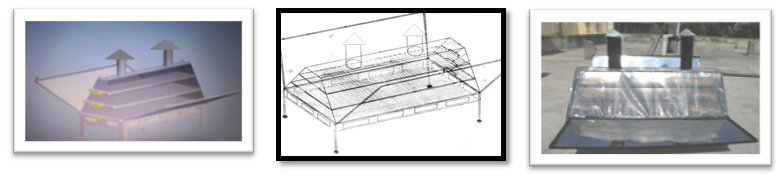

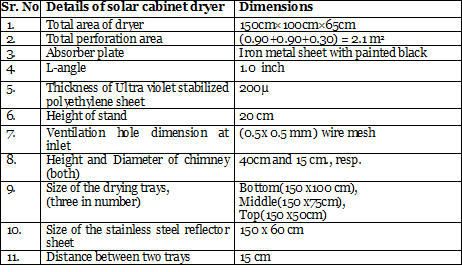

2.1 Design details of a domestic cabinet solar dryer integrated with stainless steel reflector. A domestic cabinet solar dryer integrated with stainless steel reflector having capacity of 5 kg/batch was designed and fabricated. The cabinet was fabricated in trapezoidal shape having bottom frame size (150 x 100 cm) and top (150 x 20 cm) by using L-angle of 2.54 cm x 3mm thickness. Top(150 x 50 cm) middle (150 x 75 cm) and bottom (150 x 90 cm)sliding trays were fixed in the cabinet at a vertical distance of 15 cm fixed on L angle of 2.54 cm size. The tray was fabricated in wire mesh and M.S. flat. The air vents were provided at the bottom both sides (100 x 20 cm) and front and back (150 x 20 cm). The cabinet was covered with ultra violet stabilized polyethylene film of 200 micron thickness. On the top two chimneys were provided to remove hot moist air. The chimney (40 cm height and 15 cm dia.) were fabricated by using 2.0 mm M.S. sheet. Two stainless steel reflectors (150 x 60 cm) were fabricated and fixed on the two sides of the cabinet above the air vents. The provision was made to change the angle of the reflectors so as to track the sun. The schematic views of domestic solar cabinet dryer is shown in Plate 1.

Plate 1. Schematic view of domestic cabinet solar dryer integrated with reflectors

2.2 Mechanism of dryer with stainless steel reflector sheet heating system: The stainless steel reflector sheet heating system is one of the simplest, cost-effective and efficient heating. During day hours, solar energy transmitted through polyethylene sheet in the solar dryer and inside temperature of dryer increased due to greenhouse effect. The direct solar radiations were reflected by the reflectors into the cabinet which is painted black. The radiations were absorbed by the black color and thus increase the cabinet temperature. The heat accumulated in the cabinet was used for removing the moisture from the product. The draught was created due to removal of hot and moist air from the chimney and the fresh air entered into the cabinet.

2.3 Detail of experimental set up A domestic cabinet solar dryer integrated with stainless steel reflectors system (5 kg/batch capacity)was developed and installed at Department of Unconventional Energy Sources and Ele. Engg.,Dr. PDKV, Akola. It consisted of cabinet, drying trays, UV stabilised PE sheet as a cladding material, stainless steel reflectors and two chimneys. A schematic view of a domestic cabinet solar dryer integrated with stainless steel reflectors system during the experimental work is shown in plate 2.

Plate 2. Performance evaluation of domestic solar dryer for drying of green chilly

The solar dryer consisted of stainless steel reflectors of area 1.5m2 attached with drying chamber. The reflector was fabricated in stainless steel sheet of 1 mm thickness. The base of the cabinet was fabricated by using 1 mm thick Aluminium sheet coated with black paint so as to absorb the maximum incident solar radiation. The absorber plate was placed directly at the bottom of the dryer. The capacity of the dryer was about 5 kg of chilli per batch. The dryer was oriented to east-west to maximize the solar radiation incident on the dryer. In order to evaluate the performance of the domestic cabinet dryer integrated with stainless steel reflector, the green chilli were dried in the system. During the experimentation following parameters were measured: temperature, solar intensity, ambient temperature, drying temperature in the dryer, drying time. On these basis moisture content, drying rate and moisture ratio of the product were determined.

2.4 Instrument used :Following instruments were used during the experimentation: Digital Hygrometer, thermometer anemometer, pyranometer, electrical convecting oven: digital weight balance were used during the experimentation. The dryer was designed and fabricated with the following dimensions: Design details of domestic solar cabinet dryer assisted with reflectors:

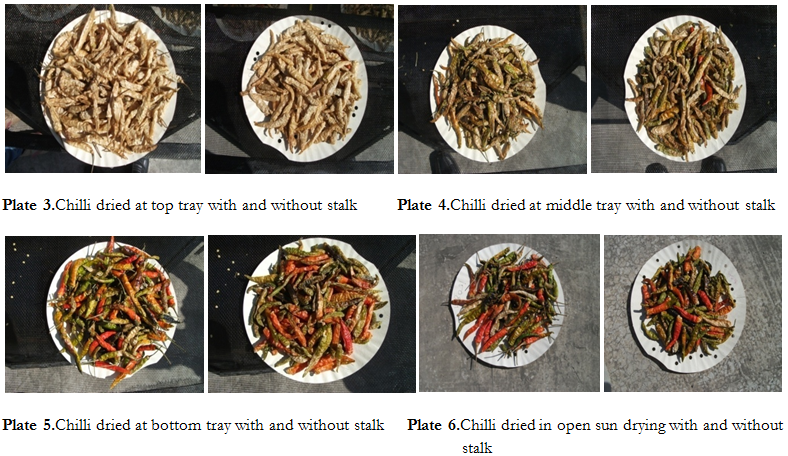

2.5 Performance evaluation of domestic solar dryer: Performance of the system was evaluated at no load and full loading condition by drying green chilli. Under no load conditions, air temperature inside the cabinet dryer across at different trays was recorded at definite intervals of time during a typical sunny day. In full load testingFive kg fresh green chilli was spread in the drying trays uniformly and loaded in the cabinet dryer for drying in the month of December. Two samples of green chilli were prepared as with stalk and without stalk of 250 g each. (Plate 3-6). The quantity of the product loaded, initial moisture content of the product and M.C. at specified interval were measured. The product drying time, drying temperature in the cabinet dryer, solar intensity, moisture content of the product during drying, ambient temperature, relative humidity were measured during the experimentation. The increase of temperature due to use of stainless steel reflectors during the day was measured. Temperature was measured using of pre-calibrated thermometers. Humidity of the ambient air was obtained from psychometric chart by measuring wet bulb and dry bulb temperature of air. During efficiency of the solar dryer was estimated.

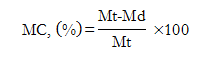

2.5.1 Determination of moisture content: The quantity of moisture present in a material was determined on wet basis and expressed as percentage. About 10 g samples of the material was taken and kept in a convective electrical oven, which were maintained at 85±1°C until constant weight has reached. The initial (Mt) and final mass (Md) of the samples were recorded with the help of electronic balance. The moisture content (MC) on wetbasis was calculated by using following equation. The procedure was repeated for every one hour interval till the end of drying of green chilli.

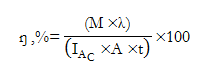

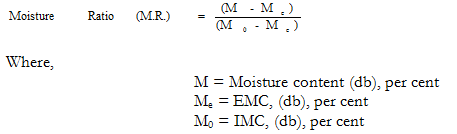

Thermal efficiency: The thermal efficiency (ηth) of the solar dryer was estimated by using equation,

Where, M = Mass of water evaporated, kg λ = Latent heat of vaporization, MJ kg-1 Iac = Total solar radiation, MJ m-2 A = Collector area m2 t = Time, sec. and efficiency of dryer was to be found during the experimental work is given below

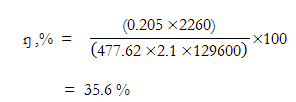

Determination of moisture ratio:

The Moisture ratio of the produce was computed by following formula (Chakraverty, 1988).

Where,

M = Moisture content (db), per cent

Me = EMC, (db), per cent

M0 = IMC, (db), per cent

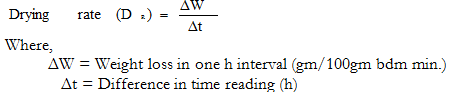

Determination of drying rate:

The drying rate of produce sample during drying period was determined as follows (Chakraverty, 1988).

3.0 RESULTS AND DISCUSSION

This chapter comprises the results obtained from the study of performance evaluation of domestic cabinet solar dryer integrated with stainless steel reflector for drying chilli. The study involved development of cabinet solar dryer with integrated reflectors heating system for 5 kg/batch capacity. The results obtained are discussed as below.

3.1 To evaluate the performance of domestic solar cabinet dryer integrated stainless steel reflectors.

3.1.1 No load testing of cabinet solar drying system.

Performance of the cabinet solar drying system was evaluated at no load condition. The average temperature in the solar cabinet dryer integrated with stainless steel sheet heating system during the day time at specific interval were recorded. The maximum average temperature in the solar dryer was found to be 52oC during day time at 13.00 hrs with corresponding ambient temperature and solar insolation of 300C and 752.2 W/m2.The temperature increased slowly during morning till late afternoon and after that it started declining during evening. On the first day the average ambient temperature was found to be 25oC and solar intensity was 451.7 W/m2.

3.1.2 Temperature developed in drying chamber of cabinet solar dryer.

The temperature developed in the solar cabinet dryer integrated with stainless steel sheet heating system during day time without exhaust fan was recorded. The temperature in the solar dryer was observed to be 32 to 62°C during day time. The temperature raised slowly during morning till late afternoon and after that it started declining during evening and reached to near ambient. The ambient temperature was observed to be 15 to 32oC and solar intensity was34.8 to 752.2 W/m2.

3.1.3 Heat supplementation using stainless steel reflector sheet during no load condition.

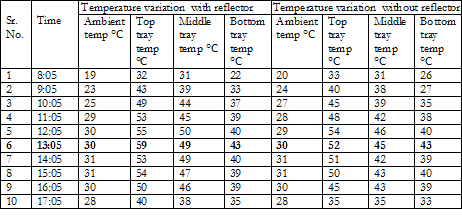

Table 1.revealed the temperature in the drying chamber due to heat supplementation by using stainless steel sheet reflecting system during no load condition and compared it with and without using reflectors. Highest temperature in the drying chamber was found to be59oC, 49oC, and 43oC in top, middle and bottom trays, respectively with corresponding ambient temperature of 30oC by using reflectors. It was observed that temperature in the drying chamber was highest in the top tray during the mid day with reflectors than without reflectors. Similarly highest temperature were found to be 540C,460C and 400C in top, middle and bottom trays without using reflectors, respectively.

Table 1 Temperature developed in the dryer with and without using reflectors under no load test

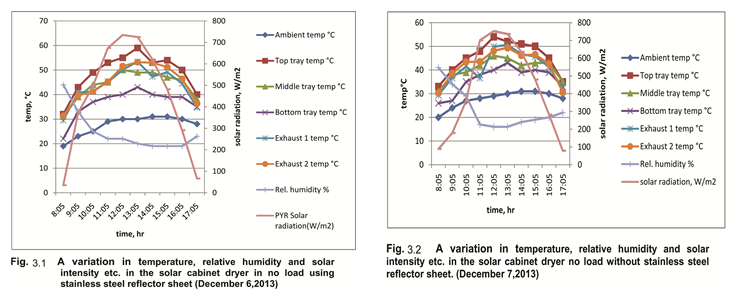

Fig. 3.1 and 3.2 showed the variation of temperature, solar intensity ambient temperature and relative humidity during experimentation. Maximum solar intensity recorded was about 752.2 W/m2 during peak sunshine hours on 1st and 2nd day of experimentation and ambient temperature was recorded 19 to 30oC. In the atmosphere, a higher relative humidity of about 44 % was recorded.

The solar cabinet dryer was evaluated for drying chilli. On first day of drying the average temperature in the solar dryer was observed in the range of 45 to 55°C. It was observed from experimental work that the ambient temperature and relative humidity during the experiment on first day of drying was observed in the range of 19 to 34°C and 19 to 23%, respectively and the solar intensity was recorded in the range of 311.3 to 703.6 W/m2. Similar trend was observed in the cabinet dryer on 2nd, 3rd and 4th day of drying However, the average drying temperature on 2nd day of drying was higher as compared to other drying days.

3.1.4 Evaluation of the dryer for drying green chilli.

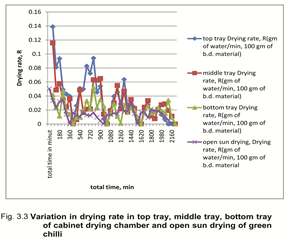

The solar dryer was tested by drying green chilli. Fig. 3.3 showed the drying rate in the solar cabinet dryer on 1st, 2nd,3rd and 4th day of drying during day time in month of December. The temperature in the solar dryer was found in the range of 45 to 55°C on drying days. The ambient temperature and relative humidity during the experiment were 15 to 34°C and 16 to 44% respectively. The solar intensity during days was found in the range of 34.8 to 752.2 W/m2.

The variation of drying rate with drying time is illustrated in Fig. 3.3 Drying time for drying chilli from initial moisture content of 83.93% (wb) to 3.21% (wb) and 2.2% (wb) with stalk and without stalk respectively at top tray was found to be 36 h in the solar dryer as compared to 104 h in the open sun drying. Drying efficiency of the drying system was estimated to be about 36%. The green chilli dried in solar cabinet dryer and in open sun drying method is shown in (Plate 3-6)

4. CONCLUSIONS

From the above summarized results, the following conclusions could be drawn:

- The cabinet dryer integrated with stainless steel reflectors system was developed and found suitable for drying green chilli.

- At no load test, the maximum temperature in the solar dryer was found to be 59°C (33-59°C) during day time in the month of December, 2013 corresponding to the average ambient temperature of 24°C (16 – 320C) and solar intensity,477.92 W/m2 (34.8 to 752. 2W/m2).

- Drying time required for drying of 5 kg green chilli for reducing moisture content of 83.93% to 3.21% (wb) was found to be 36 h in the cabinet solar dryer equipped, where as it took 104 h in the open sun drying.

- The temperature in the dryer varied between 33-62°C corresponding to the ambient temperature of 15-32°C during experimentation.

- Thermal efficiency of the solar dryer with reflector system was found to be 35.6%.

- The color of the solar dried chilli was observed to be brighter as compared to the open sun dried chilli.

References

Chua KJ, Chou SK. 2003. Low cost drying methods for developing countries. Trends Food Sci Technoly.14:519–28.

Desai, S. R.; Kumar, V. and Guruswamy, T. (2002), Performance Evaluation of Mini Multi-rack Solar Dryer for

Grapes Drying.J. Agril. Engg. Today 26 (3-4): 30-37.

Erenturk, S., M.S. Gulaboglu, S.Gultekin, 2004.The thin layer drying characteristics of rosehip.Biosyst. Eng. 89 (2):

159-166.

Esper, A. and Muhlbauer, W. 1993. Development and dissemination of solar tunnel dryers, In: Proc. of Workshop,

Drying and Conservation with Solar Energy, ISES Solar World Congress, Budapest, 22 August, 1993

Forson FK, Nazha MAA, Akuffo FO.1996. Natural convection solar crop dryers of commercial scale in Ghana:

design,construction and performance. Ambient Energy.17:123–30.

Hachemi, A. C.; Abed, B. and Asnoun, A. (1998), Theoretical and Experimental Study of Solar Dryer.Renewable Energy. 13 (4): 439-451

Hayati, O. and Rzayer, P. (2002), New Drying systems for Crops.International Journal of Globle Energy. 17(1): 106-112

Mani, A. 1980. Handbook of Solar Radiation Data for India, Madras: Allied publishers, Private Limited

Publication,1981.

Rai, G. D. (1994), Solar Energy Utilization Khanna publications, New Delhi: 1-3

Sharma, V. K.; Colangelo, A. and Spagna, G. (1994), Experimental Investigation of Different Solar Dryers Suitable for Fruit and Vegetable Drying.Renewable Energy. 6(4): 413-423.