Title: RESISTANCE (Magnesium Alloy Aggregates)-The Gateway to New Concrete Technology

Authors: Gautam Kumar & Arjun, Department of Civil Engineering

College: Sant Baba Bhag Singh Institute of Engineering & Technology, Jalandhar

The target of this thesis is to discovered and the use of Magnesium Alloy Aggregates in concrete which we called it “RESISTANCE” . It was divided as FINE RESISTANCE AGGREGATE (F.R.A.) and COARSE RESISTANCE AGGREGATE (C.R.A.). This “RESISTANCE” had cutting edge technology to draft and design it by the use of auto CAD, ANSYS Software and civil engineering applications like High Performance Concrete (H.P.C). It was concluded that the Magnesium Alloy Resistance Aggregates had the great result in all dimensions of civil engineering applications.

Key words: “RESISTANCE” , FINE RESISTANCE AGGREGATE (F.R.A.) , COARSE RESISTANCE AGGREGATE (C.R.A.). Magnesium Alloy Aggregates. High Performance Concrete (H.P.C).

INTRODUCTION

Concrete plays a major role in the development of country, it is the most used material in the construction of civil structures. We discovered the “RESISTANCE” which having the properties of magnesium alloy.

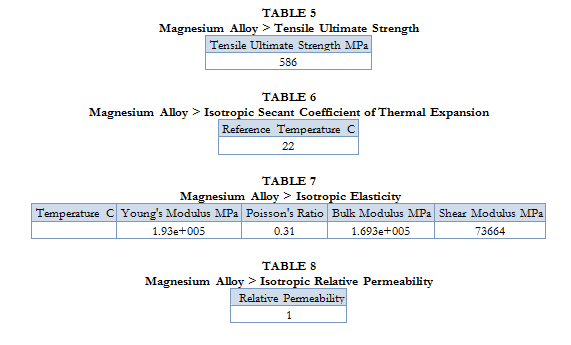

MATERIAL DETAIL: Magnesium alloy is lightest in weight (half of steel) and having high tensile strength, for more we also use magnesium wrought alloy having the proof stress of 160-240 ,Yield Strength of +600 MPa, Tensile Strength is +285 MPa with the Elongation of 2-10%

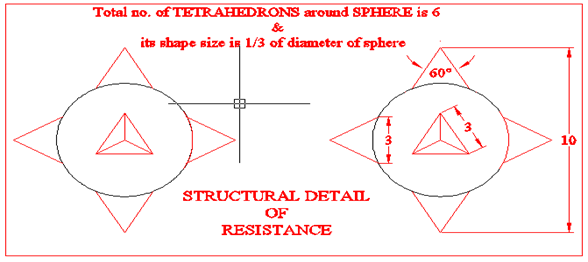

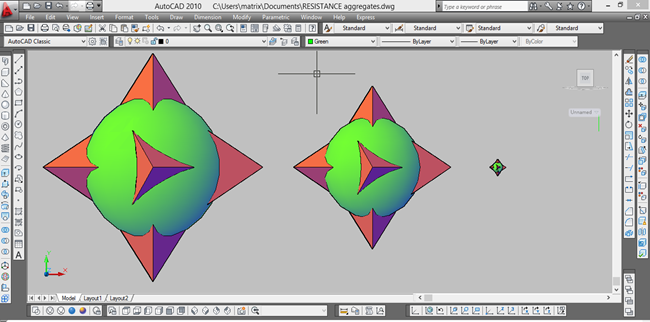

DRAFTING & ANALYSIS : “RESISTANCE” was draft in auto CAD in millimeters , The basic shape is sphere and 6 tetrahedrons around it which was 1/3 of the diameter of sphere, the whole body is in union as show in fig no 1 FINE RESISTANCE AGGREGATE (F.R.A.) size is very fine having1mm dimension and COARSE RESISTANCE AGGREGATES (C.R.A.)., dimensions are according to different size i.e 10mm,14mm.as show in fig no.2

fig no. 1

fig no. 2

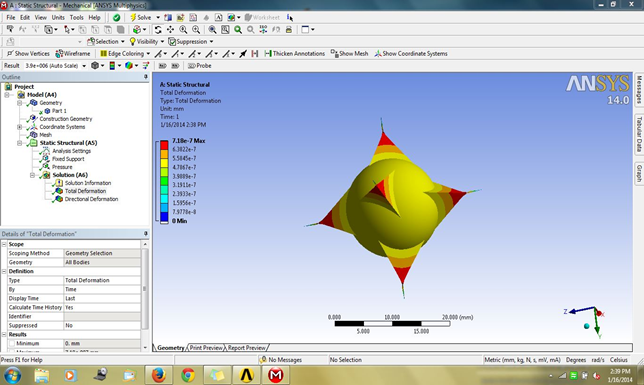

After drafting the model is import into ANSYS 14.0 software for analysis results are good as show in table 9

fig no 3

CONCRETE DESIGN PROPORTIONING

a) GRADE DESIGNATION: M25

1:1:2

1= Cement (High strength Cement)

1= Fine aggregates + 1/3 aggregate of F.R.A.

2= Course aggregates + 1/3 aggregate of C.R.A.

Note: The grade designation giving the characteristics strength requirement of concrete.

b) TYPE OF CEMENT: Portland Cement Cement 297 kg/m3

Note: Type of Cement influences the rate of development of compressive strength of concrete

c) TYPE OF AGGREGATES: Fine aggregate 20%+5% F.R.A.1mm &

Crushed Aggregates (675 kg/m3) 25%+25% C.R.A. 10 mm as total amount.

Note: Aggregates maximum normal size of aggregate to be used in concrete is according to IS code.

d) WATER 170 kg/m3

e) ADMIXTURE: Super Plasticizers(1.34 m3), Fly Ash , Silica Fume .

The process of selecting suitable ingredients of concrete and determining their relative amounts with the objective of producing a concrete of the required ultimate compressive strength , durability as economically as possible is termed the concrete mix design.

RESULTS

- COMPRESSIVE STRENGTH: Now M25 having the characteristic compressive strength (N/mm2 ) of standard concrete instead of normal concrete i.e. M30 & M35. Finally ordinary concrete take the result of standard concrete and standard concrete take the result of high strength concrete.

Grade of concrete = M25

Minimum Compressive Strength N/mm2 at 7 days = 23.5 – 40 MPa.

Specified Characteristic Compressive Strength N/mm2 at 28 days = 60 – 70 MPa.

The compressive test results indicates and increasing trend of compressive strength up to great level.

- WORKABILITY: The slump test is carried with a sample of concrete with the proportion of material and it is up to 115mm.

- PULL OUT STRENGTH: The results shows that the pull out strength is gradually increase reason of design of RESISTENCE.

- CREEP OF CONCRETE: RESISTENCE control the long term pressure or stresses on concrete, there is no change in shape.

- COMPACTION: When the compaction is in process the RESISTENCE are easily compacted without segregation.

- 6. HIGH DURABILITY.

- 7. High Abrasion Resistance.

- 8. Volume Stability.

- F.R.A. reduce the bulking of sand because it cover the 1/3 proportion of fine aggregate.

- Effective modulus of elasticity +40 (5.8×106) GPa (Psi).

- The concrete absorb the maximum moments, share and axial forces.

- The structure had great resistance to the Seismic shocks.

CONCLUSION

- Magnesium Alloy Aggregates in different sizes as FINE RESISTANCE AGGREGATE (F.R.A.)1mm and COARSE RESISTANCE AGGREGATE (C.R.A.).10mm & 14mm.

- RESISTENCE in concrete gives high strength concrete.

- High Durability Concrete and long life in severe environment.

- Self-Consolidating Concrete.

FURTHER ENHANCEMENT

FINE RESISTANCE AGGRIGATES (F.R.A.) may be in other shapes also i.e. Dodecahedron shape & Icosahedron shape.

REFERENCE

- Light Material News no 47.03, 23.11.03 pp.2-4.

- Wikipedia (www.wikipedia.com), Magnesium Alloy.

- Yoshitito Kawamura ,Kentaro Hayashi, Akihisha Inove, Material Science Researchers,JAPAN,Rapid Solidified Powder Metallurgy Mg97Zn1Y2 Alloy with Excellent Tensile Yield Strength above 600 MPA.

- Bronfin B ,Aghion E, VON Buch F,Schumann S and Friedrich H, Proceeding of the 6th International Conference Magnesium Alloys and their Application.

- M.Yaqub & Imaran Bukhari, Effect of size of course aggregate on compressive strenght of high strength concrete , 16 August 2006

- Burnet & Wolsifer,High Strength Concrete , Melbourne Australia Concrete International, April 1989.

- Neville, Adam M , Aggregate bond and modulus of elasticity of concrete ACI materials journal V.94 No 1 Jan.-Feb. 1997 pp 7174.