Technical Paper Title: AGRO MACHINE

Authors:Ravipati Bharadwaj, 2nd BTech,Mechanical

College: JNTU college of Engineering, Anantapur

AGRO MACHINE

ABSTRACT

Do you imagine a machine that can do complete work of agriculture with out any presence of man? You may think this is impossible. But we are introducing the first type of this kind in the world named “AGROMACHINE”. The main work of this machine is drilling holes in the farm, releasing seeds, releasing water, close hole , move forward to particular distance and again do the described steps. More over this machine cannot cause any pollution and is ecofriendly. This machine can revolutionize the present day agriculture. In the further sections, one can able to get an idea about the construction, working, highlights…etc of AGROMACHINE

INTRODUCTION

The agriculture sector in India is contracting year by year. There are several reasons including lack of labor, high cost of production etc. by observing these facts, we came to a strong determination of creating the machine which can do complete agriculture. Since the aim of mechanical engineer is to create a eco-friendly machine, we research for three months and create this model. Since the machine can able to work without presence of any person, the labor problem was solved. Since there is no requirement of tractor (for some crops only) etc, the cost of production is also reduces. Since this machine cannot use any type of fuel, it cannot cause any pollution and is ecofriendly.

METHODS

Since I am studying UG-2(b .tech 2 year), i find little bit difficult while doing research. However with the good cooperation of friends i complete this project successfully. Here are the steps i follow for successful completion of project.

- Data collection– maximum data i get is from the class lessons. Class subjects like kinematics of machinery and dynamics of machinery plays an important role in this model formation By referencing many of these text books and clarifying doughts, we collect some more information from the net.

- Model development– i first analyzed the basic working principles involved in the model such as types of gears to be used to transform the motion between different shafts , gear trains, cams ,valve opening mechanisms .next i moved on to the schematic diagram of the machine. We got the machine design. i start doing the prototype with the help of cardboard sheets. At initial stage we do not know the complete mechanism. But by arranging each cams, gears, shafts etc, i get the correct model which is theoretically correct. i.e, i know only the working of each component. But by proper arrangement according to working principle, i successfully completed that prototype.

CONSTRUCTION DETAILS

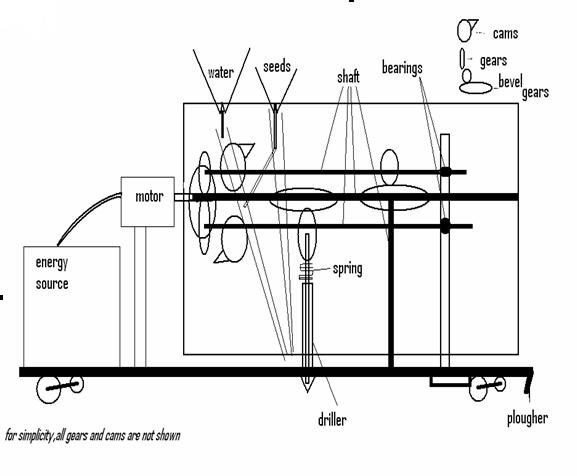

The above figure indicates the sectional front view of AGRO MACHINE. Since there are many number of gears ,cams etc for simplicity all are not shown in figure. the following are construction details of this machine.

DETAILS

- NAME OF MACHINE AGROMACHINE

- SIZE OF MACHINE 100cm*50cm*70cm (l*b*h)

- WEIGHT OF MACHINE 10-15 kg (depends up on material)

- MATERIAL USED based upon type of soil, climate etc (carbon steel,Aluminum bronze, wood etc) and materials having High Ultimate strength, high corrosion resistance. )

- ADDITIONAL SUGGESTION use amorphous carbon coating at joints for easy Lubrication

- BASE MATERIAL impreg timber or metal faced plywood is best

- WATER AND SEED CHAMBER nickel or asphalt or cork etc are used

MATERIAL

- PLOUGHER MATERIAL aluminum bronze, cork etc

- GEARS MODULE M= D/T mm (0.3, 0.4…45, 50,55,…)

- CAM PRESSURE ANGLE depends up on location of chamber

- CAM FOLLOWER knife edge followers

EXPLANATION AND WORKING

The above figure represents the structure of the agro machine .since there are presence of many gears, cams etc, all of them are not shown in figure. the overall description of machine is explained in several important parts..

- Source– the energy source for this machine may be battery, fuel cell, and solar energy etc .this source is mainly required for running of motor or servos.. However, I use battery for simple construction. but I recommended solar energy as it is suitable even for remote area also..

- Motor and shaft– this is the main part of machine. In this the shaft is run by means of motor. Many gears and cams are run by means of this shaft .this shaft is also considered as main shaft. this shaft is supported by bearings as shown in figure. In order to avoid the deflection or bending of shafts, additional balancing weights are used.

- Secondary shafts –these are run by means of gears attached to the main shaft. There are 2 secondary shafts. By means of cams attached to these shafts , the open and closing of valves of the grain and water chambers are takes place according to the cycle of operation. the supporting and balancing are similar to the main shaft.

- Driller– by means of bevel gears connected to the main shaft the driller works. For cyclic working of driller, I newly invented and introduced new type of gear called SEMI GEAR, in which tooth are present only on one side of gear. this SEMI-BEVEL GEAR MECHANISM is used for successful downing of driller. . With the help of spring the driller retrieve back after drilling

In addition to above described parts there are several other important parts like plougher, bearings, etc .by proper arrangement of all the gears (by means of proper designing), the working is done in step wise continuously.

WORKING

The working of agro machine is easily explained by means of following steps

- Power –This is the first step in working of machine. In this step the battery is made ON. Thus the power is supplied for the running of motor. and by means 3-POINT STARTER arrangement, the motor is get ready for running at rated speed. However because of loading, the motor runs at low speed. As described above, the primary or main shaft, which is connected to motor is also came into action. Since there is gear connection between primary and secondary shafts, all the three shafts came in to action, but at low speed.

- Drilling- This step is considered to be the second step of working. Moreover this is the most complicated step and high energy consuming step. About 60% power of total cycle is consumed in this step only. It is because of simple reason, as power is much required for drilling the land. By means of SEMI-BEVEL GEAR, which is powered by means of primary shaft, the driller drills land, when tooth of semi-bevel gear mated with lower gear. And driller stops drilling when untoothed part of semi bevel gear comes in to action.(no mating takes place). Thus drilling stops. By means of helical spring arrangement, the driller is retrieved back. In general The diameter of this semi-bevel gear is much large (10 times diameter of normal gear or gear ratio>10).

- Pouring- this is the useful step of the cycle. Through this step only, there is consecutive successful pouring of seeds and water into the driller. this step can be done by means of CAM connected by means of secondary shaft as shown in figure. Moreover this step is similar CAM-FOLLOWER arrangement in 4-stroke engine. Since it is not economical to pour high amount of seeds and water in drilled hole, care must be taken the outlet hole of chamber must be closed within seconds(4-7 seconds). Hence I introduce cam of large diameter and medium pressure angle in the machine.

- Closing & moving– this is the final step in the cycle. However this step is combination of two intermixed steps i.e., moving forward by closing drilled & filled hole. This is done by means of bevel gear arrangement on the primary shaft as shown in the figure.

Thus there is completion of cycle and the next cycle starts. It is clearly representing that there is no need of manpower in any step.

DERIVATION

- We know that the voltage equation of DC shunt motor is given by

V=Eb + Ia*Ra where v=applied voltage through battery, Eb=back emf, Ia, Ra=armature current,

Armature resistance

- By multiplying with armature current Ia, we get power equation i.e, V*ia= Eb*Ia+Ia^2*Ra where V*Ia=supply power,

Eb*Ia=mechanical power

Ia^2*Ra=Armature losses.

- Hence from observation, efficiency of Dc motor=70%.(reference machines lab ,jntu-anantapur)

- Shaft torque: it is defined as torque which is available at shaft (primary shaft of agro machine) of motor for doing useful work. (Tsh)

Tsh= 9.55*output/N-m, where N=speed of motor

- Brake horse power(BHP): the HP developed by shaft torque is called BHP.

BHP=useful output power=2*3.14*N*Tsh/60*746 Hp

Thus one get the output power at primary shaft of agro machine by the above formulae.

Since we know that from fundamental law of gearing,

D1/D2=T1/T2=N2/N1 where D1.D2=diameter of mated gears

T1, T2=number of teeth of gears

N1, N2=speeds in RPM

Suffixes 1 & 2 indicate the gears on primary and secondary shafts.

- Thus one can get the respective unknown terms from the above equation. By knowing the diameters and speed of primary shaft, we can easily calculate the speed, torque, power of secondary shafts. Hence by knowing the speed of secondary shafts, we can easily calculated the efficiencies of all the 4 steps successfully.

- There exits different efficiencies for various steps. Each steps efficiency is get by,

Efficiency= (output/input) *100

Overall efficiency is get by taking the average of all the 4 step efficiencies

Hence overall efficiency= (step1+step2+step3+step4) efficiency/ 4

- One can get maximum efficiency for step 3(pouring) & minimum efficiency for step 4(drilling)

In general the overall efficiency of agro machine varies from (55%-65%) approximation(by taking speed of primary shaft under load=10% of rated speed, diameter of cam=5d,G=10) ..

RESULTS

- Very low cost(use impreg timber as base)

- Easily repaired.

- The machine works in four steps

- Machine work efficiently (55-65%)

- Successful, useful in seeding of any types of seeds, especially vegetable seeds

- The power source can be either solar, battery, fuel cell etc.

- Great reduction in man power at the field

- Wear of the machine parts is very less hence more durable.

- Seeds wastage can be maximum reduced.

- Best suitable for areas where there is water scarcity.

- Machine is perfectly balanced by proper arrangements of parts

- Very high stable(since flat base surface)

DISCUSSION

As one motor is used to run the entire system , its energy is transmitted in different modulations ,however the existing friction can be reduced by lubricants .since seeding is done for particular distance hence it is applicable for vegetables and some of the commercial crops. Here the maximum power is required only for drilling. We use small energy source like solar, fuel cell etc. Since there is regulated flow of seeds in to the hole there is maximum reduction in the wastage of seeds.

since I do not arrange arranged any turning mechanism, the machine will go perfect straight. However we are sincerely trying for arranging proper turning mechanism.

CONCLUSION

The machine is made only by the proper arrangement of gears and cams there is a continous four step cycle. It is most economical. While designing the machine we designed a new type of gear known as semi gear. The semi gear is used for regulated drilling .By the completion of the machine we got clear idea of using the gears. Again we are claiming that This machine can revolutionize the present day agriculture.

ACKNOWLEDGMENTS

As we made only the prototype which cost less financial support is not required. The basic concepts are from the class lessons we thank our sir. Prof.Govindarajulu garu for his clear explanation of the concepts.

REFERENCES

ü Class notes

ü Theory of machines/khanna publications

ü Theory of machines / khurmi/ s.chand

ü Theory of machines / thoas bevan/ cbs publishers

ü Material science and engineering

ü Basic electrical engineering/bakshi